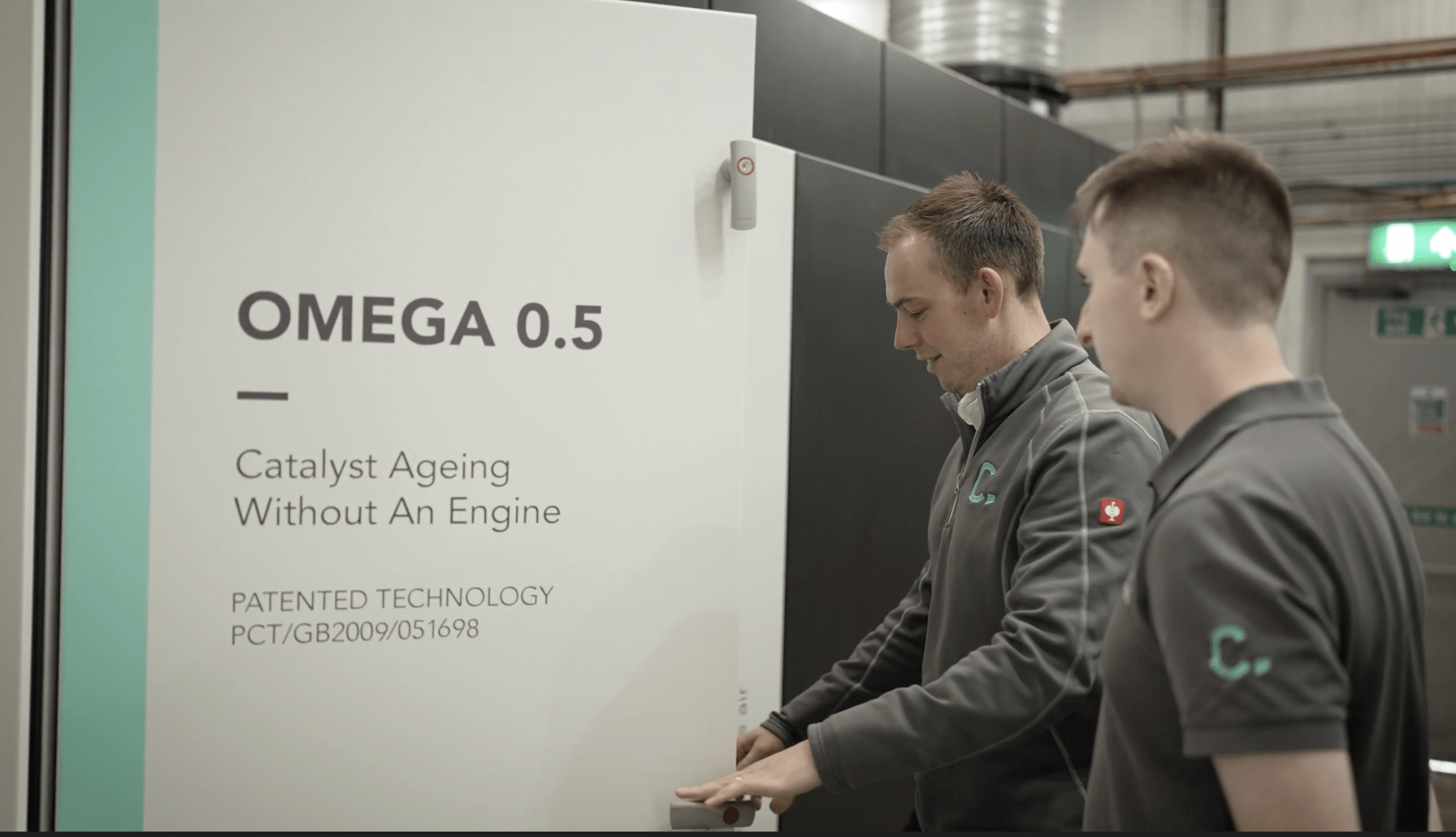

ClimaHtech is an acceleration system towards decarbonisation using advanced climate technologies.

It is a platform to generate green hydrogen, bio-hydrogen and gHreen e-fuels with complementary systems for carbon capture and hydrogen compression.

NEW PROJECT

Hydensity – In partnership with TEREX and Wrightbus

Launch of £8.1 million Project HyDensity to demonstrate decarbonised quarrying operations through ClimaHtech’s Hydrogen & E-Diesel production by 2025.

NEW PROJECT

Clean Maritime Demonstrator Competition (CMDC)

Techno-economic Study of ClimaHtech Innovative Clean Maritime Solutions is part of the Clean Maritime Demonstration Competition Round 4 (CMDC4), funded by the UK Department for Transport (DfT) and delivered by Innovate UK.

CLIMAHTECH

Designed for Industry with multiple benefits.

Cost

competitive

More energy efficient

Utilises waste heat sources

Uses existing supply chains

Net zero fuels from renewable sources

GET IN CONTACT

Let’s drive innovation together

Titanic Quarter Belfast

+44(0)289045510

Knowledge Hub