Catalyst Manufacturers

Contact an ExpertCATAGEN APPROACH

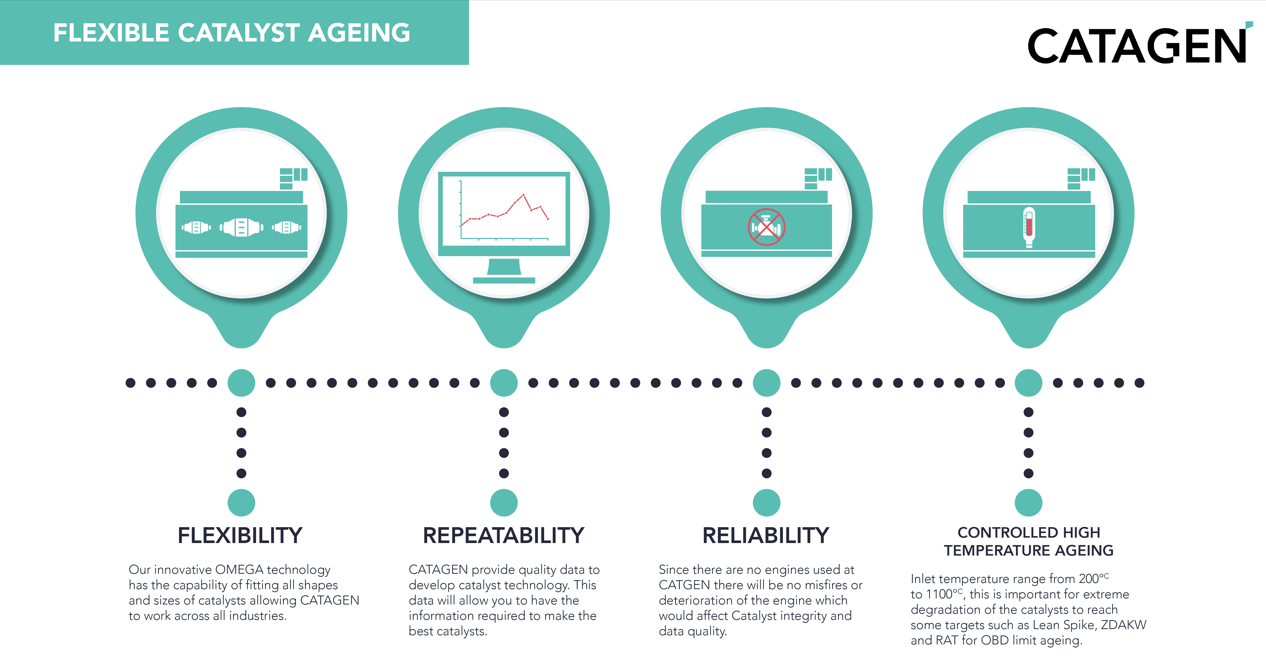

CATAGEN helps automotive OEMs meet emissions targets faster, with higher accuracy and repeatability. Our unique OMEGA technology can replicate engine flow rates, temperatures and gas compositions for any kind of engine. Accredited by UK Vehicle Certification Agency (VCA), Applus IDIADA, TUV ATEEL and ECO Cert.

We offer tailored services to support OEMs to meet aftertreatment development milestones and emissions compliance (homologation). We help manage development issues with the catalyst ageing process and help manage cost implications such as PGM prices and the rising cost of fuel.

The OMEGA is capable of thermal and chemical degradation of aftertreatment components. Our chemical degradation is through a bespoke poisoning setup which can be used for a range of different compounds such as, sulphur and phosphorus which can help with OBD limit ageing.

Supporting our partners obtain certification with

CATAGEN powered by 100% renewable energy