ClimaHtech CEMENT

GET IN CONTACTOVERVIEW

CEMENT – High temperature boosted decarbonisation

CATAGEN’s ClimaHtech system can accelerate the decarbonisation of cement production by complementing the use of alternative fuels and flue stack capture.

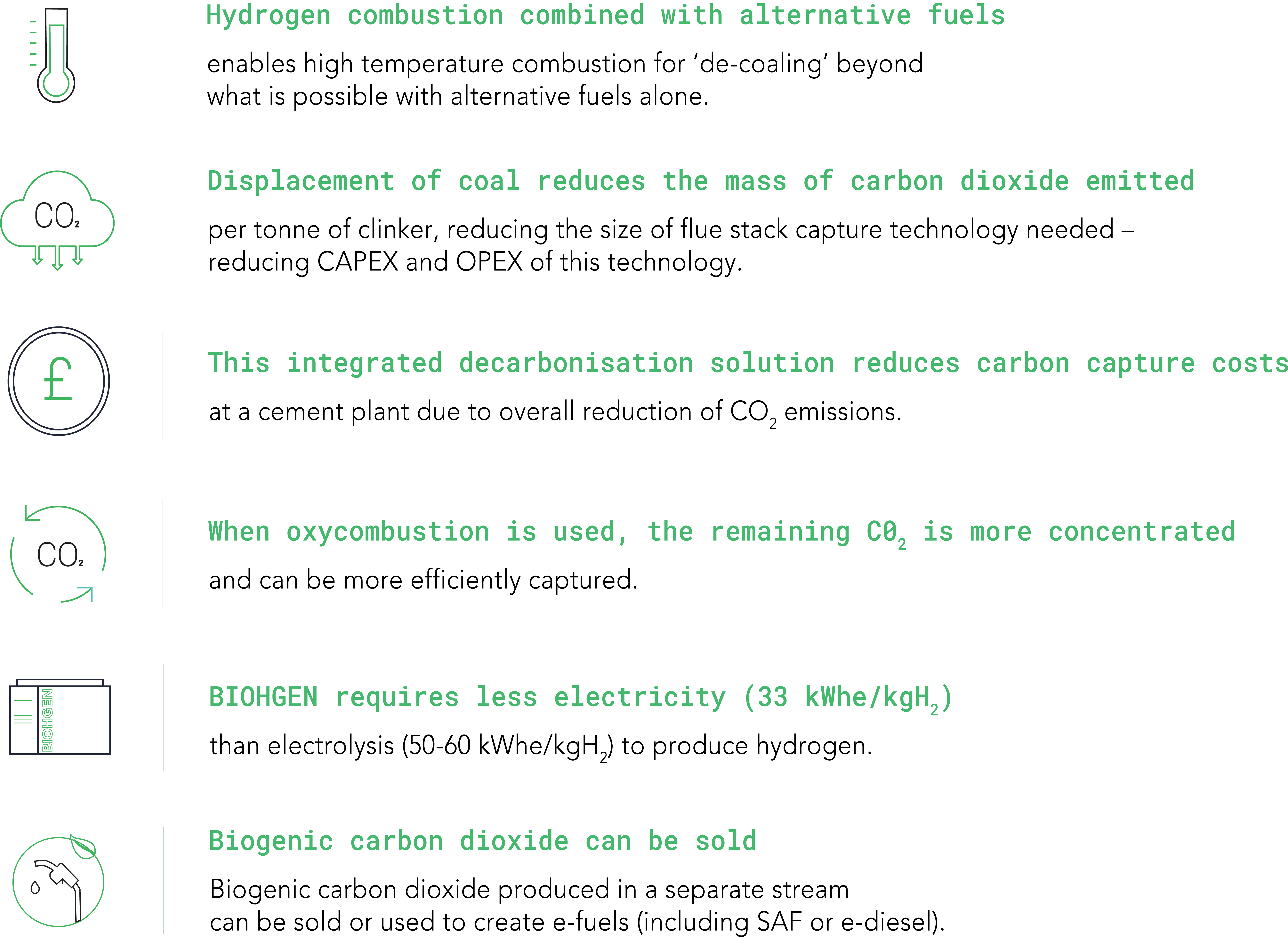

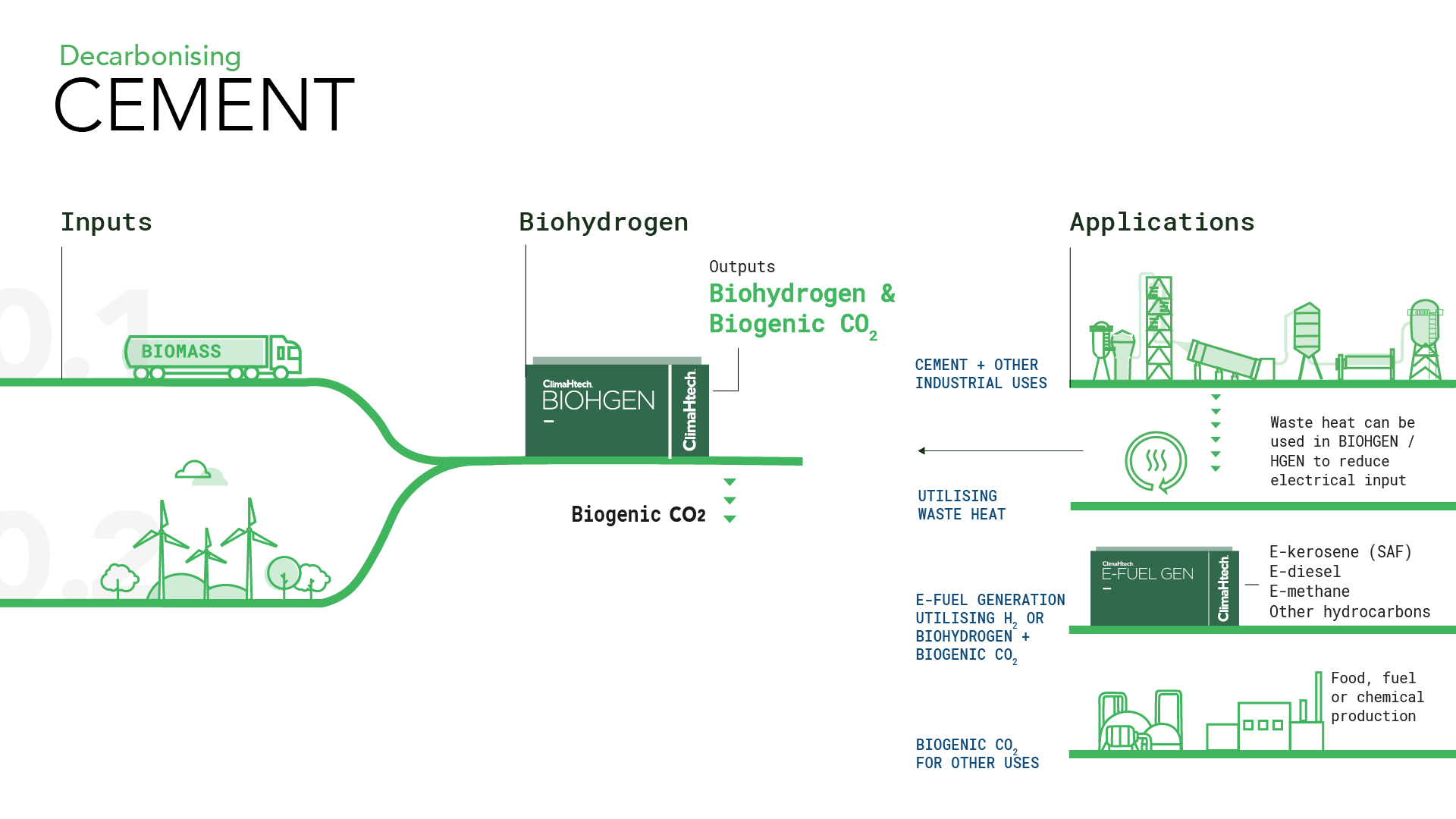

Due to its high operating temperatures (up to 1500 ˚C), large energy demand, and high carbon intensity, the cement industry is an ideal application for utilising hydrogen in the kiln to boost temperature. The ClimaHtech BIOHGEN reactor can produce biohydrogen on site with a direct feed to the kiln.

Intrinsic emissions from cement production primarily result from the breakdown of limestone into clinker and the subsequent heating of clinker to produce cement. The calcination process emits 60% of total production emissions, with 40% coming directly from burning fossil fuels. Utilising hydrogen reduces the amount of fossil fuel in the kiln therefore reducing emissions from the flue stack.

BIOHGEN uses CATAGEN proprietary technology to produce cost-effective biohydrogen from sustainable organic waste streams and renewable energy. This energy efficient fuel can accelerate the decarbonisation of cement plants.

Utilising other ClimaHtech technolgies in the cement industry:

The biogenic carbon dioxide produced by BIOHGEN can be combined with hydrogen to produce a range of fuels including SAF and e-diesel via ClimaHtech E-FUEL GEN offering a decarbonised solution for a range of other sectors.

ClimaHtech HGEN technology can also be used to generate the necessary hydrogen for decarbonisation of cement and creates oxygen, which can be used for oxycombustion in compatible cement works.

TECHNOLOGY IN INDUSTRY

A CATAGEN study showed how to decarbonise Mannok Cement operations by at least 18%

Implementation of solutions at Mannok will displace carbon savings equivalent to removing 49,000 cars from roads on the island of Ireland. The solutions identified in this study could be applied to cement production worldwide where sufficient renewable energy and sustainable biowastes are available.

- Biohydrogen generation from waste biomass can generate larger volumes of hydrogen with less renewable energy required compared to electrolytic hydrogen generation. The use of BIOHGEN technology could reduce the carbon intensity of cement produced at this site by a further 18 percent by reducing fossil fuel use.

We are very excited to be working with the CATAGEN team, who have demonstrated a deep level of technical ability and competency during the feasibility work. I have no doubt that Mannok will derive significant value from the work already completed, with many new opportunities for collaboration now presenting that we would not have considered before. Achieving Net Zero is now the primary goal for our business and I expect CATAGEN will play a significant role in our achieving that goal, which we expect will have major benefits for the sector overall.

It is fantastic to see firsthand the strides that CATAGEN is making to drive the transition toward Net Zero. Heavy industry will need innovative solutions to decarbonise rapidly and CATAGEN are an example of the history of innovation in Northern Ireland that can tackle these globally significant challenges.”

PARTNER WITH US

ClimaHtech CEMENT Lead

Ralph Lavery

Ralph is part of the CATAGEN Commercialisation Team focusing on the cement sector.

ClimaHtech has a unique offering for cement, steel and glass for decarbonisation. Interested in ClimaHtech’s decarbonisation solution for Cement or other industrial processes?

GET IN CONTACT

Let’s drive innovation together

Titanic Quarter Belfast

+44(0)289045510