Catalyst Ageing

Contact an expert

Our unique OMEGA technology can reproducibly replicate engine flow rates, temperatures, and gas compositions for: Standard gasoline or diesel; Hybrid powertrains; E-Fuels, hydrogen combustion, biofuels, ethanol engines or natural gas engines.

The OMEGA is capable of thermal and chemical degradation of aftertreatment components and other non-automotive catalyst applications. Our chemical degradation is through a bespoke poisoning setup which can be used for a range of different compounds such as, sulphur and phosphorus.

AKRAPOVIC names CATAGEN as their Catalyst ageing company for 2024

Urban Potočnik, R&D Director at Akrapovič commented:

”Choosing to work with CATAGEN was a strategic decision for us, driven not only by the cost-saving benefits and fast turnaround times but also by the role sustainability plays in our business strategy. The precision demonstrated in the tests is amazing, with surprisingly low deviations. The emissions test results of the aged catalysts, expertly aged by CATAGEN for us, authentically mirrored the real data observed on our reference motorcycle.”

STANDARD BENCH CYCLE (SBC)

CATAGEN use the Standard Road Cycle (SRC) data that our partners supply to calculate the Bench Ageing Time (BAT) or we conduct the SBC at a prescribed time and temperature criteria on request of our partners.

CATAGEN can modify the SBC for higher temperatures for a reduction in overall ageing time.

CATAGEN has developed its own precision diagnostic embedded in our test software, the CATAGEN Ageing Metric. It allows real time second tracking and monitoring of temperature, gas composition and flow rate throughout an ageing cycle giving us results that are repeatable to within 0.5%.

RAPID CATALYST AGEING

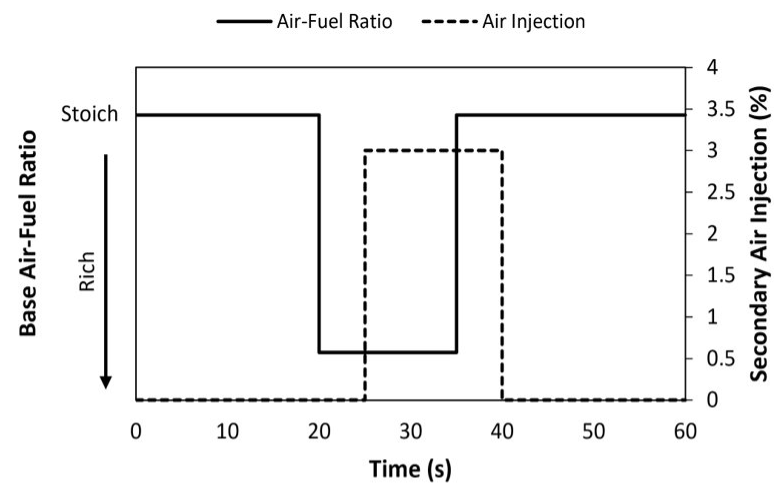

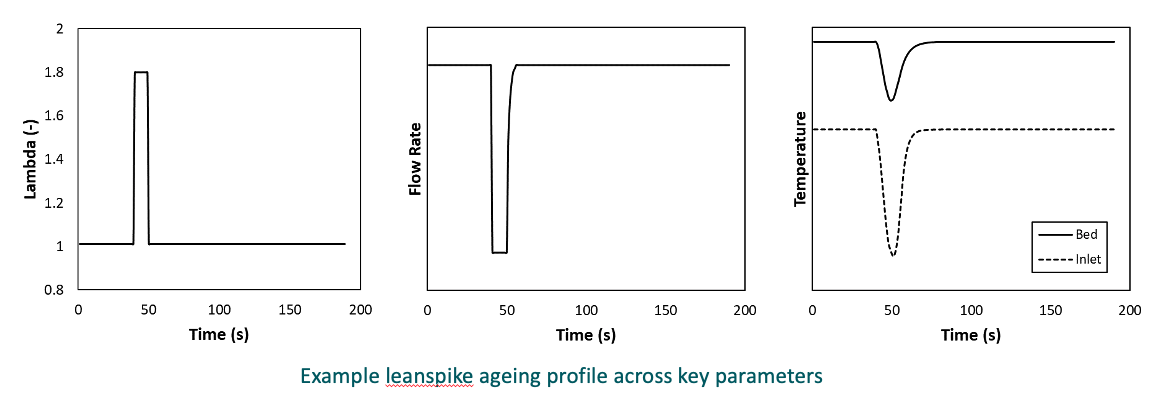

Fuel cut ageing uses a combination of high temperature and lean conditions to age aftertreatment systems.

Catalyst temperature, fuel cut duration and frequency can be altered to match individual customer requirements.

The example below shows bench ageing carried out following lean spike protocol:

180 second stoichiometric – 10 second fuel cut

Flow Rate at catalyst of 40g/s

REFORMER CATALYST AGEING

CATAGEN employs our proprietary OMEGA technology, an advanced synthetic recirculating gas reactor designed for accelerated durability testing of reformer catalysts in applications like Solid-Oxide Fuel Cells (SOFCs). Through precise simulation of catalyst inlet conditions encompassing mass flow rate, temperature, and gas composition, CATAGEN revolutionises catalyst testing.

Our state-of-the-art facility is equipped to handle natural gas and features de-sulfurization units to effectively mitigate sulfur related challenges during testing.

Notably, our facility has been granted approval for the controlled utilisation and management of hydrogen throughout the testing processes.

OBD (THRESHOLD) LIMIT

Current emissions legalisation requires OEMs to have fully tested On Board Diagnostic (OBD) systems. To test these systems OBD aged catalysts and sensors are essential to prove the OBD will detect a deteriorated catalyst.

CATAGEN uses a series of high temperature dynamic ageing techniques with intermittent performance checks such as OSC or LO tests to age components to meet a customer’s individual OBD requirements across all sectors.

We do not over age our OBD components when reaching the OBD limit.

CUSTOM OEM CYCLES

With patented technology CATAGEN can use a series of control techniques to create new aftertreatment ageing cycles to match individual customer requirements.

Our technology allows accurate control of catalyst temperature, gas injection and flow rates to create a full range of custom transients. These control mechanisms allow for accurate, repeatable and reproducible ageing cycles.

CATAGEN’s thorough testing services have played a crucial role in aiding Ducati’s journey towards achieving developmental goals and accelerating market entry. By integrating these testing capabilities with their extensive catalysis expertise, CATAGEN has effectively supported Ducati in overcoming the intricate challenges posed by Euro 5+ emissions standards.

CATAGEN powered by 100% renewable energy