Characterisation Performance Tests

Contact an expertOXYGEN STORAGE CAPACITY TEST (OSC)

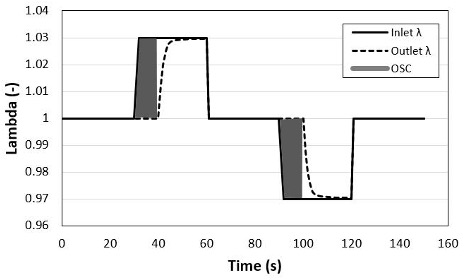

The CATAGEN OSC measurement procedure involves cycling the catalyst between lean and rich conditions, with full oxidation and reduction of the ceria at each condition. The OSC value is calculated through several different methods across both oxidation and reduction reactions, including analysis of the λ signals, analysis of raw emissions data and analysis of the reactant delivery providing a pure measurement of performance of OSC on the catalyst.

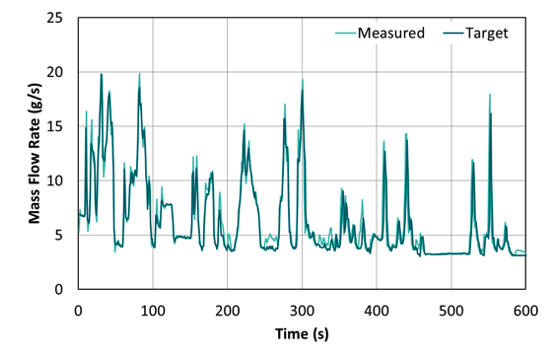

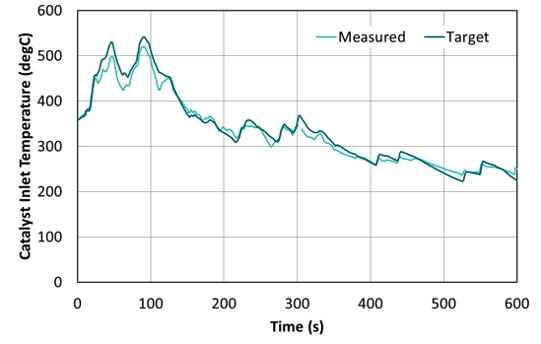

CATAGEN can replicate vehicle conditions including the mass flow rate and engine out temperature at the measurement point on the vehicle. This allows for very strong correlation on OSC measurement between CATAGEN & our partners.

LIGHT OFF TEST (FAST/SLOW)

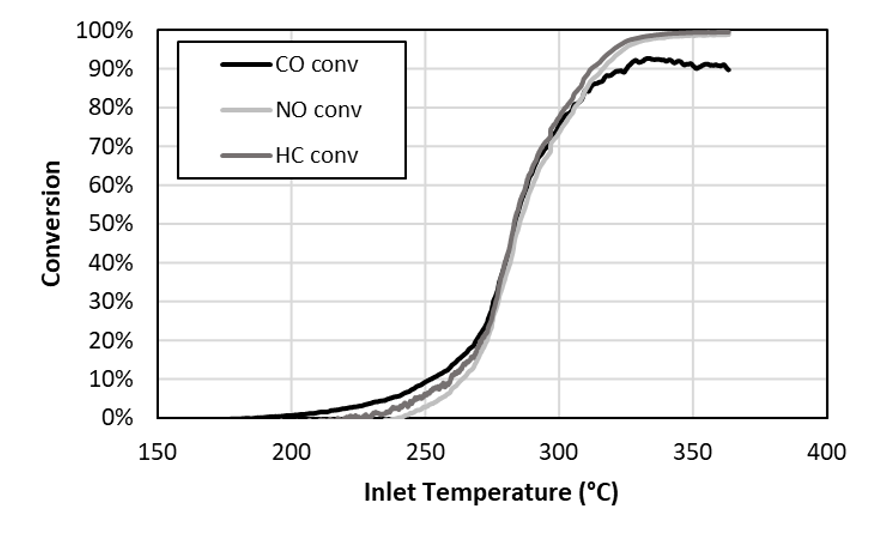

Catalyst degradation can be tracked through measurement of light-off performance. Two separate reproducible light-off tests are carried out at CATAGEN – a fast and a slow composite light-off (CO, HC and NO). The difference in light-offs is the inlet temperature ramp rate, a fast light-off ramp rate is 10°C per second and a slow light-off ramp rate is 10°C per minute.

Emission conversion is measured using Horiba MEXA ONE analysers, with the 50% conversion point of greatest interest.

A range of gas concentrations, flow rates and ramp rates can be explored with our partners.

LAMBDA / AIR FUEL RATIO SWEEP (AFR)

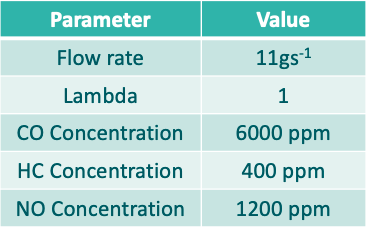

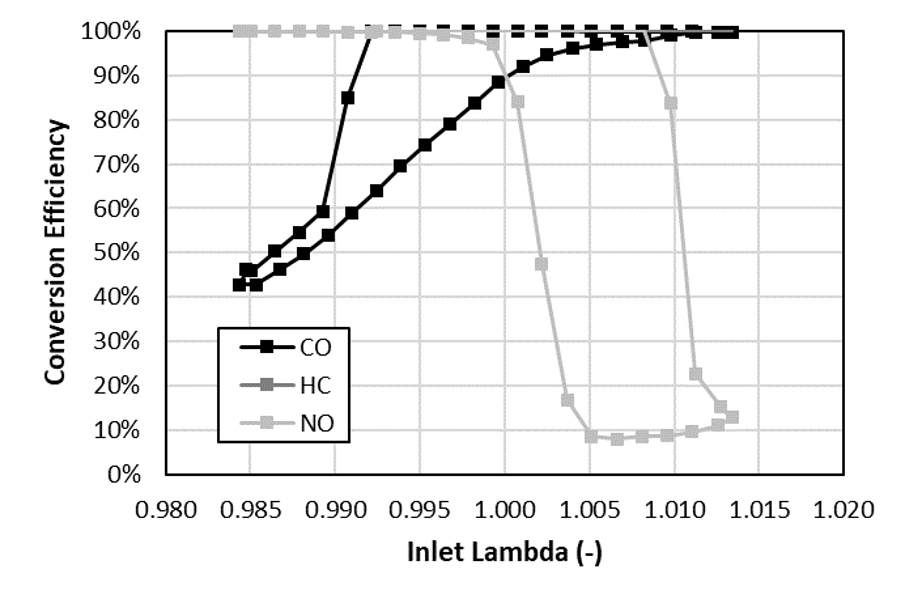

Lambda sweep tests are used to assess PGM and washcoat degradation. The test protocol follows a cyclic oscillation of lambda, with fixed HC and NO, and variable CO and O2 concentrations as specified in the table.

Fixed lambda ramp rates are employed, facilitating an assessment of the impact of OSC on emissions conversion. As with the light-off tests, emissions conversion is measured with Horiba MEXA ONE analysers.

DRIVE CYCLE TEST (WLTC)

Measurement of vehicle emissions performance can be a time and labour-intensive process. This is particularly so when considering bench aged catalysts, as these must be removed from the ageing bench and remounted in a test vehicle before testing can commence. To support our partners in this challenge; CATAGEN has developed a drive cycle emulation testing service offering, based on the patented OMEGA test reactor that can be performed on the catalyst following ageing.

ADDITIONAL SERVICES

Knowledgebase Advanced Offering

‘Golden Catalyst replication’ – cloning on-road vehicle aged catalysts

Virtual testing services & modelling

PGM Thrifting Services (Precious Group Metals)

Catalyst poisoning – doping with multiple compounds

Fuel & Lubricants – understanding catalyst performance

Collaborative Research & Development Projects to Clean Air Development Partnership

Advanced Characterisation Services

Precious Metal Loading Measurement

Transmission Electron Microscopy (TEM)

Scanning electron microscopy (SEM)

X-ray diffraction

Brunauer, Emmett and Teller (BET) surface area measurements

Supporting our partners obtain certification with

CATAGEN powered by 100% renewable energy