Catalyst Ageing Without An Engine

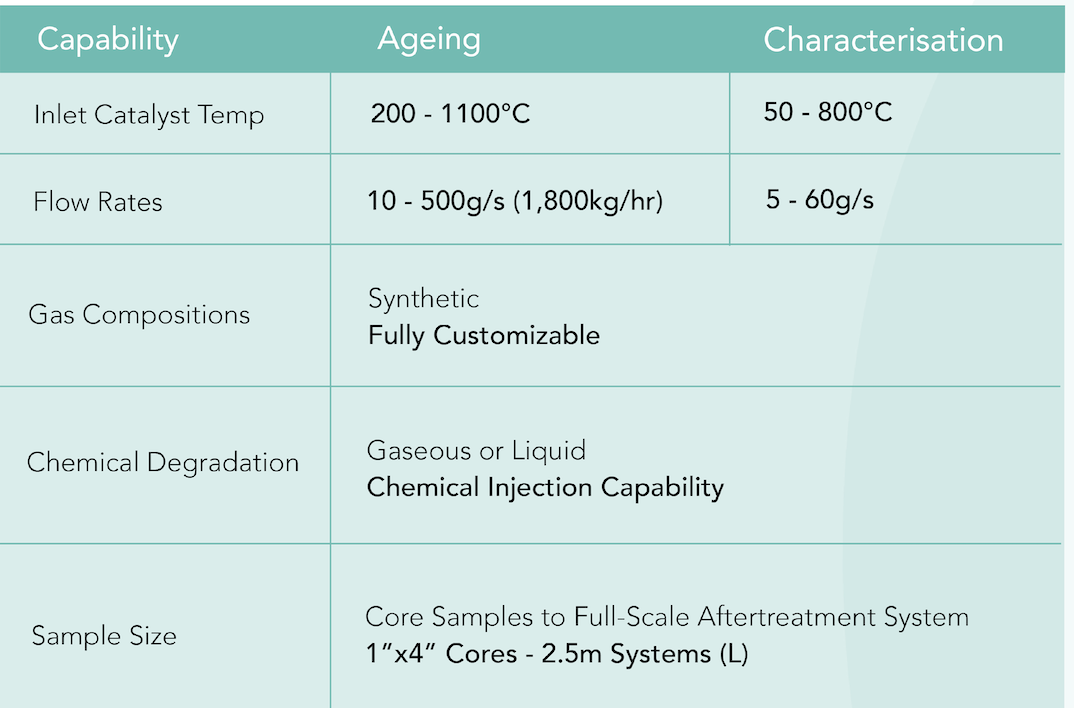

Contact an expertOur unique OMEGA technology can reproducibly replicate engine flow rates, temperatures and gas compositions for standard gasoline or diesel engines, hybrid powertrains, e-fuels, hydrogen combustion, biofuels, ethanol engines and natural gas engines.

OMEGA enables both thermal and chemical degradation of aftertreatment components, as well as other non-automotive catalyst applications. Chemical degradation is delivered through a bespoke poisoning setup that can be used with a range of compounds such as sulphur and phosphorus.

Catalyst Ageing Without An Engine

STANDARD BENCH CYCLE (SBC)

CATAGEN uses Standard Road Cycle (SRC) data supplied by our partners to calculate the Bench Ageing Time (BAT). We can also run the SBC to specific time and temperature criteria when required.

The SBC can be adapted to higher temperatures to shorten overall ageing time.

Our proprietary CATAGEN Ageing Metric is embedded in our test software and provides real time, second-by-second monitoring of temperature, gas composition and flow rate throughout each ageing cycle. This delivers highly consistent results with repeatability within 0.5%.

RAPID AGEING

Fuel cut ageing applies high temperatures under lean conditions to accelerate the degradation of aftertreatment systems. Catalyst temperature, fuel cut duration and frequency can be fully adjusted to align with specific customer test plans.

Example lean spike protocol:

-

180 seconds stoichiometric, followed by 10 seconds fuel cut

-

Catalyst flow rate: 40 g/s

REFORMER CATALYST AGEING

CATAGEN uses our proprietary OMEGA technology, an advanced synthetic recirculating gas reactor designed to deliver accelerated durability testing for reformer catalysts in applications such as Solid Oxide Fuel Cells (SOFCs). By precisely replicating catalyst inlet conditions, including mass flow rate, temperature and gas composition, CATAGEN provides a highly controlled and repeatable environment for catalyst ageing.

Our facility is fully equipped to operate with natural gas and includes dedicated de-sulfurisation units to address sulphur related challenges during testing.

The site is also approved for the controlled use and management of hydrogen, ensuring safe and reliable testing of hydrogen related reformer catalyst applications.

OBD THRESHOLD LIMIT

Current emissions legislation requires OEMs to validate fully tested On Board Diagnostic (OBD) systems. This includes the use of OBD-aged catalysts and sensors to demonstrate that the system can reliably detect catalyst deterioration.

CATAGEN applies high temperature dynamic ageing techniques, combined with intermittent performance checks such as OSC or LO tests, to age components precisely to each customer’s OBD requirements across all sectors.

We ensure components are aged accurately to the defined OBD threshold and are never over-aged.

CUSTOM OEM CYCLES

With patented technology CATAGEN can use a series of control techniques to create new aftertreatment ageing cycles to match individual customer requirements.

Our technology allows accurate control of catalyst temperature, gas injection and flow rates to create a full range of custom transients. These control mechanisms allow for accurate, repeatable and reproducible ageing cycles.

What Our Customers Say About Us

Trusted by leading OEM’s and Catalyst Manufacturers such as Akrapovic, Ducati, Zenvo, LeoVince and SC Projects for our fast turnaround, precise catalyst ageing emissions data, and cost-saving benefits.

![Webinar 11 - Email Footer [Recovered]](https://catagen.com/wp-content/uploads/2024/04/ISO-Certification-Website-Footer-05-1.jpg)

Supporting our partners obtain certification with

CATAGEN powered by 100% renewable energy