Project HYDENSITY

GET IN CONTACTLaunch of £8.1 million Project HyDensity to demonstrate decarbonised quarrying operations through Hydrogen & E-Diesel

CATAGEN, Terex and WRIGHTBUS have been awarded £6.27 million funding by the UK Department for Energy Security and Net Zero (DESNZ) as part of the Red Diesel Replacement Phase 2 competition. In total this is part of a £8.1 million project to decarbonise non road mobile machinery.

HYDENSITY

Overview

The project will deliver a decarbonised end-to-end demonstration of a Terex crusher and screener, powered by green hydrogen and e-diesel at a site

in Northern Ireland in November 2025, utilising CATAGEN’s ClimaHtech E-FUEL GEN and COMPRESSOR technology in the Terex Powerscreen Premiertrak 450E and Chieftain 1700XE and WRIGHTBUS is supporting the development

of a mobile hydrogen refueller.

TEREX

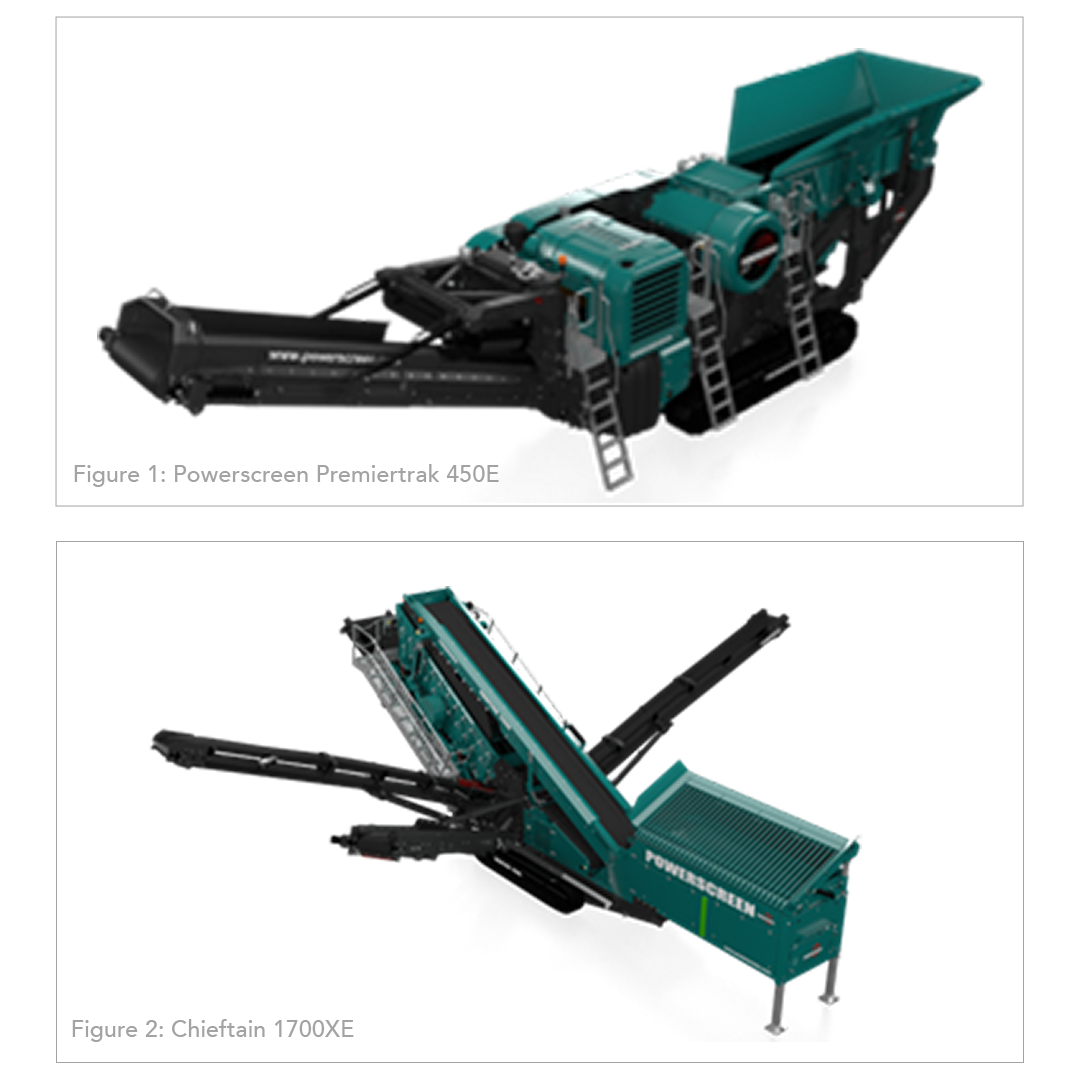

Terex will deliver 2 new electrified systems comprising a crusher and a screener, figure 1 & 2. The hydraulic driveline will be replaced with more efficient electrical components, improving efficiency and lowering power requirements. The current diesel engines will be used for operation on e-diesel as standalone similar to current operation but with electrified powertrain.

The dual-fuel (hydrogen/e-diesel) engine and hydrogen alternatives will be provided as separate gensets and plugged into the system drivelines. This will provide full off-grid operation at a quarry site, demonstrating zero emission potential but with the ability to plug into a power-grid if available. This approach will allow testing and evaluation of the system compared to the current diesel / hydraulic systems and a comparison of e-diesel versus dual fuel versus hydrogen combustion.

CATAGEN

CATAGEN is developing a process for new liquid e-fuel production using its energy efficient patented E-FUEL GEN reactor. This is a new approach to create an energy dense hydrogen fuel carrier that uses renewable energy sources. Hydrogen has many issues with storage and handling, our e-fuel carrier offers increased energy density and less complex transport and storage requirements, particularly for heavy duty vehicles where energy density is crucialto efficient operation. This means that heavy duty applications can use e-diesel as an alternative to power fleets in those difficult to decarbonise industries.

This system uses renewable energy to synthetise liquid hydrocarbon fuel from captured CO2 and renewable hydrogen. The patented E-FUEL GEN will be further developed and combined with new processes to create an advantageous technology for production of E-diesel.

CATAGEN is developing the ClimaHtech COMPRESSOR, a high-pressure hybrid pumping system for hydrogen storage and dispensing. Current methods are relatively inefficient, expensive to manufacture and display various operational issues in use, such as long duty cycles and overheating.

CATAGEN’s ClimaHtech COMPRESSOR maximises available fuel usage and has improved thermal efficiency, contributing to lower capital costs.

This will be integrated with the hydrogen dispensing system in a novel manner to extend the available capacity. This reduces the complexity and increases the efficiencies of the gas delivery from the storage tanks and between the supply and receiver tanks.

WRIGHTBUS

Having developed the World’s First Hydrogen Double-Deck Bus, WRIGHTBUS will support the development of a mobile refueller for delivery of hydrogen to the quarry test site, working closely with CATAGEN to interface / integrate with the mobile compressor.

This system will integrate the CATAGEN hybrid compression system to provide a unique, lightweight, mobile dispensing system for transport of hydrogen to the test site and for

dispensing of the fuel on-site.

GET IN CONTACT

Let’s drive innovation together

Titanic Quarter Belfast

+44(0)289045510

October 2, 2024

October 2, 2024