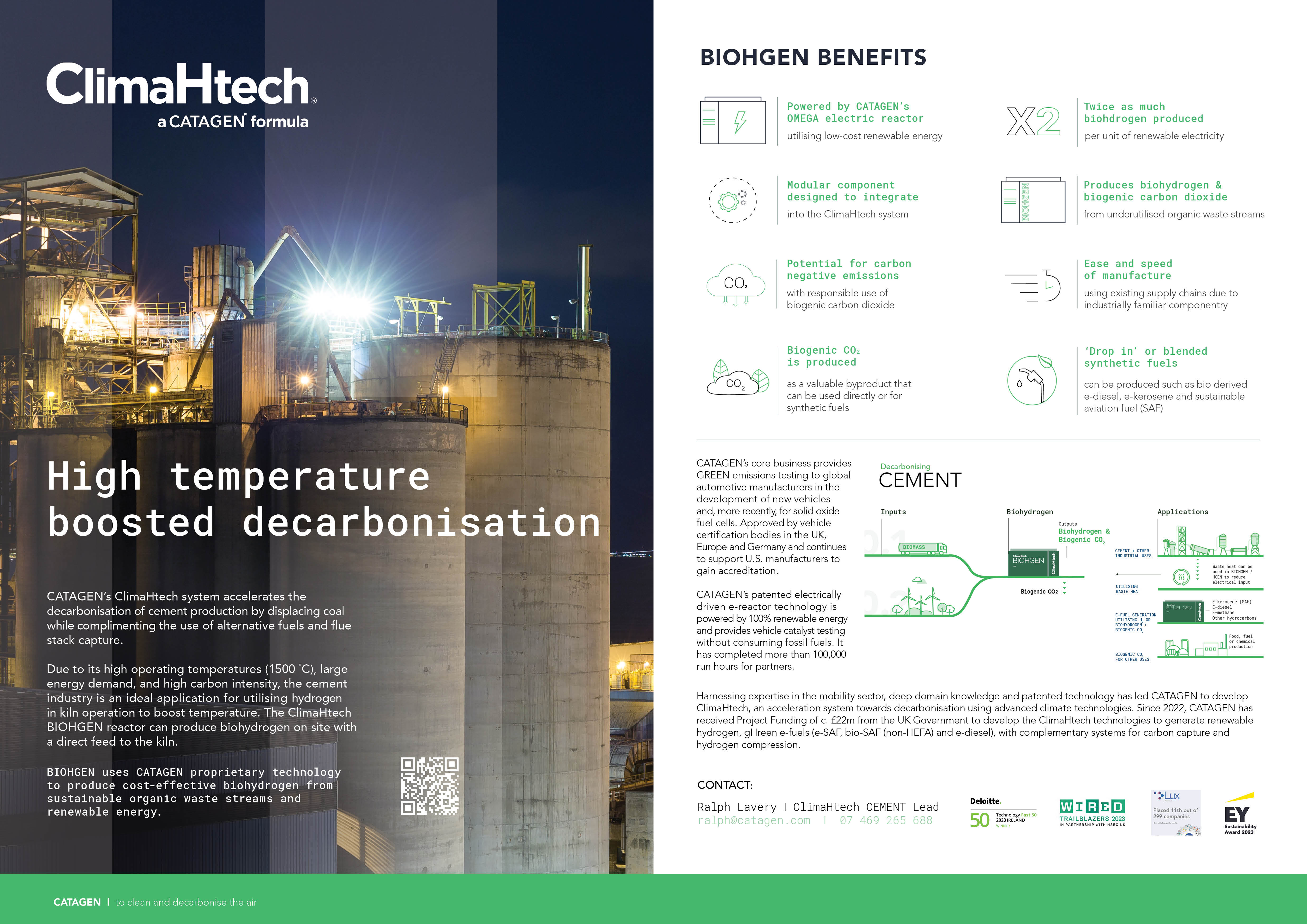

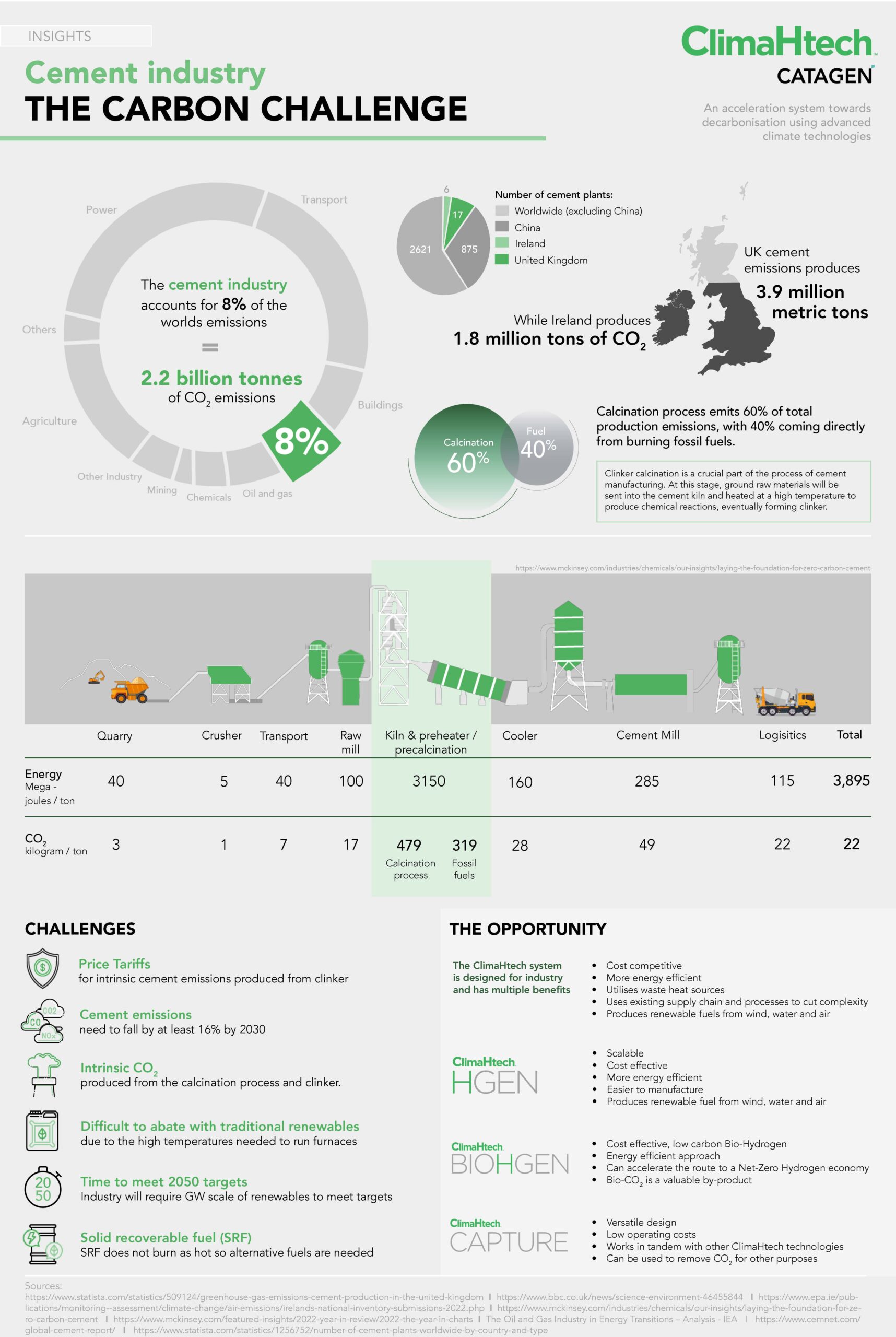

CATAGEN’s ClimaHtech system accelerates the decarbonisation of cement production by displacing coal while complimenting the use of alternative fuels and flue stack capture.

Due to its high operating temperatures (1500 ˚C), large energy demand, and high carbon intensity, the cement industry is an ideal application for utilising hydrogen in kiln operation to boost temperature. The ClimaHtech BIOHGEN reactor can produce biohydrogen on site with a direct feed to the kiln.

BIOHGEN uses CATAGEN proprietary technology to produce cost-effective biohydrogen from sustainable organic waste streams and renewable energy.

View the document below or learn more at ClimaHtech CEMENT – Catagen

Decarbonising Aviation: CATAGEN at the Farnborough International Airshow 2024

The CATAGEN team visited Farnborough International Airshow this year, which took place on the...

CATAGEN’s ClimaHtech System Decarbonising Cement and Quarrying

CATAGEN’s mission is to clean and decarbonise the air and that is why we are focused...

PRESS RELEASE : CATAGEN first to submit sustainable aviation fuel sample to EU SAF Clearing House

CATAGEN, a net-zero technologies company, is the first to submit a sample of its...

CATAGEN and Powerscreen exhibit at Hillhead Quarrying, Construction and Recycling Exhibition

CATAGEN and Powerscreen teams exhibiting at Hillhead Event Last week, CATAGEN’s CTO and...

CATAGEN Named as one of the UK’s Most Innovative Green Technology Companies in 2024 by BusinessCloud

CATAGEN has been named as one of the EnviroTech 50 by BusinessCloud, which lists the UK’s most...

CATAGEN Sponsors the Hydrogen Energy Association’s Annual Conference

CATAGEN is delighted to be a silver sponsor of the Hydrogen Energy Association's Annual Conference...