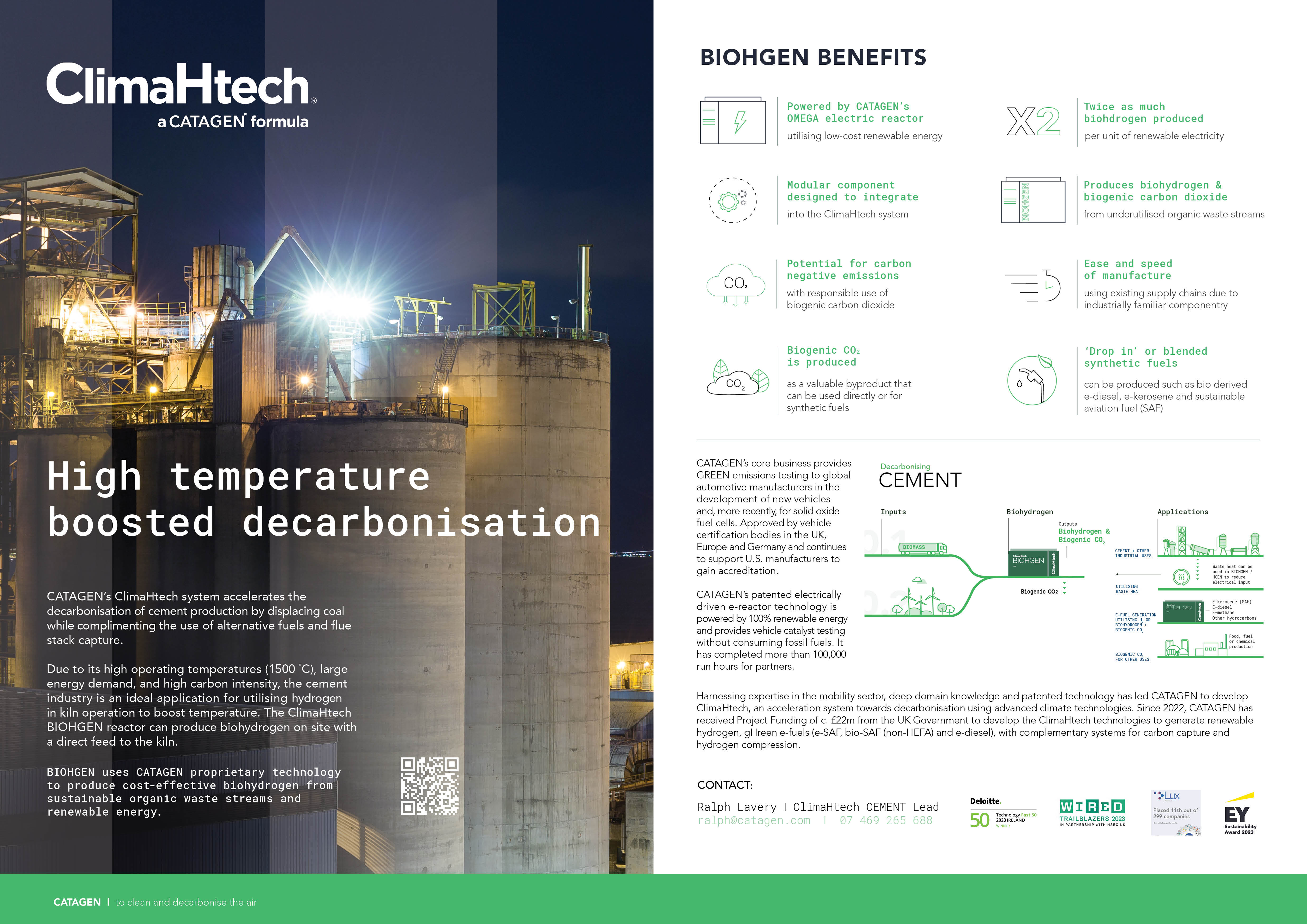

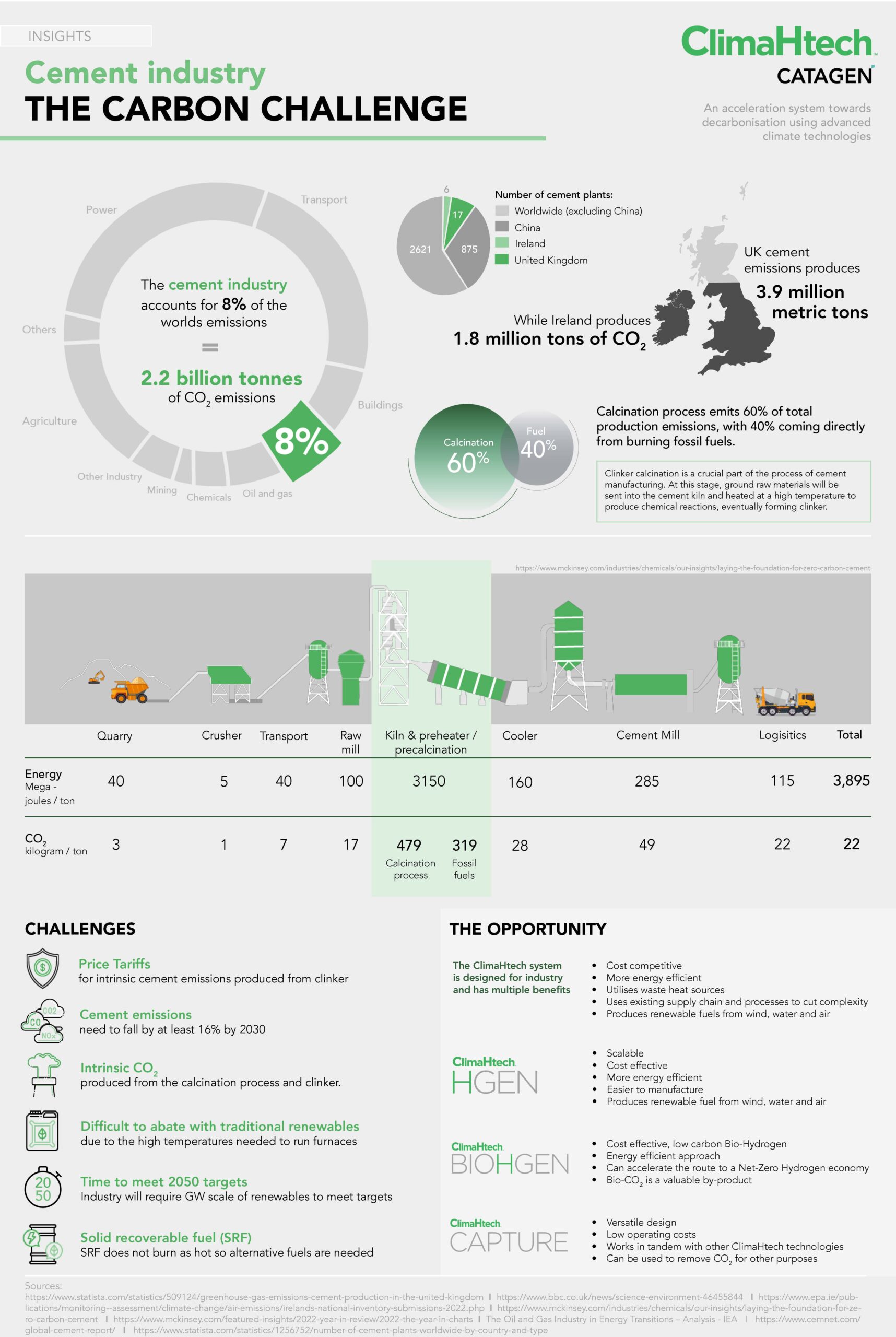

CATAGEN’s ClimaHtech system accelerates the decarbonisation of cement production by displacing coal while complimenting the use of alternative fuels and flue stack capture.

Due to its high operating temperatures (1500 ˚C), large energy demand, and high carbon intensity, the cement industry is an ideal application for utilising hydrogen in kiln operation to boost temperature. The ClimaHtech BIOHGEN reactor can produce biohydrogen on site with a direct feed to the kiln.

BIOHGEN uses CATAGEN proprietary technology to produce cost-effective biohydrogen from sustainable organic waste streams and renewable energy.

View the document below or learn more at ClimaHtech CEMENT – Catagen

CATAGEN Sponsors the Hydrogen Ireland Conference in Titanic Belfast: Delivering a Balanced Pathway to Net Zero

CATAGEN is proud to be a platinum sponsor of the Hydrogen Ireland Conference, set to take place on...

Department for Energy Security and Net Zero awards CATAGEN £4.9 million to develop Biohydrogen Reactor

Department for Energy Security and Net Zero awards CATAGEN £4.9 million to develop Biohydrogen...

July Employee Spotlight – Mark Frazer

ABOUT ME Hi, I'm Mark Frazer, Test and Maintenance Technician at CATAGEN. I support the Catalyst...

CATAGEN receives 2 BEIS awards to develop new Net Zero Technologies

Belfast based CATAGEN have successfully secured initial funding to produce green hydrogen and e-fuels from the UK’s Department for Business, Energy and Industrial Strategy (BEIS)

CATAGEN March Newsletter

CATAGEN provides physical and virtual emissions testing to global automotive OEMs and industry...

CATAGEN launches new monthly newsletter

CATAGEN has launched a monthly newsletter to showcase its latest news, insights and technology...