Written By Ralph Lavery, Net Zero Applications Engineer

When was the last time you boarded a flight? Was it for work, a holiday, or to visit family? In just over a century, aviation has transformed our world, turning distant continents into close neighbours. Yet this extraordinary connectivity comes with a carbon cost. The aviation industry is responsible for around 2.5% of global CO₂ emissions and remains one of the hardest sectors to decarbonise.

To put this into perspective, the UK emits 0.77% of the world’s CO₂ emissions, and the EU emits around 6%.

While cars and buses are moving toward electrification, and hydrogen is being explored for rail and heavy goods vehicles, aviation faces tougher constraints. The physics of flight limits our options. Batteries are too heavy for all but the shortest journeys, and storing hydrogen safely at the scale needed is highly complex and far from commercial readiness. For long-haul, high-altitude flights, there is currently no viable alternative to liquid hydrocarbon fuels—enter Sustainable Aviation Fuel (SAF).

SAF offers a promising pathway. It can be used with today’s aircraft and infrastructure, requiring no radical redesign. According to the International Air Transport Association (IATA), if we continue flying on fossil-derived jet fuel, aviation emissions will reach 1.8 billion tonnes annually by 2050.

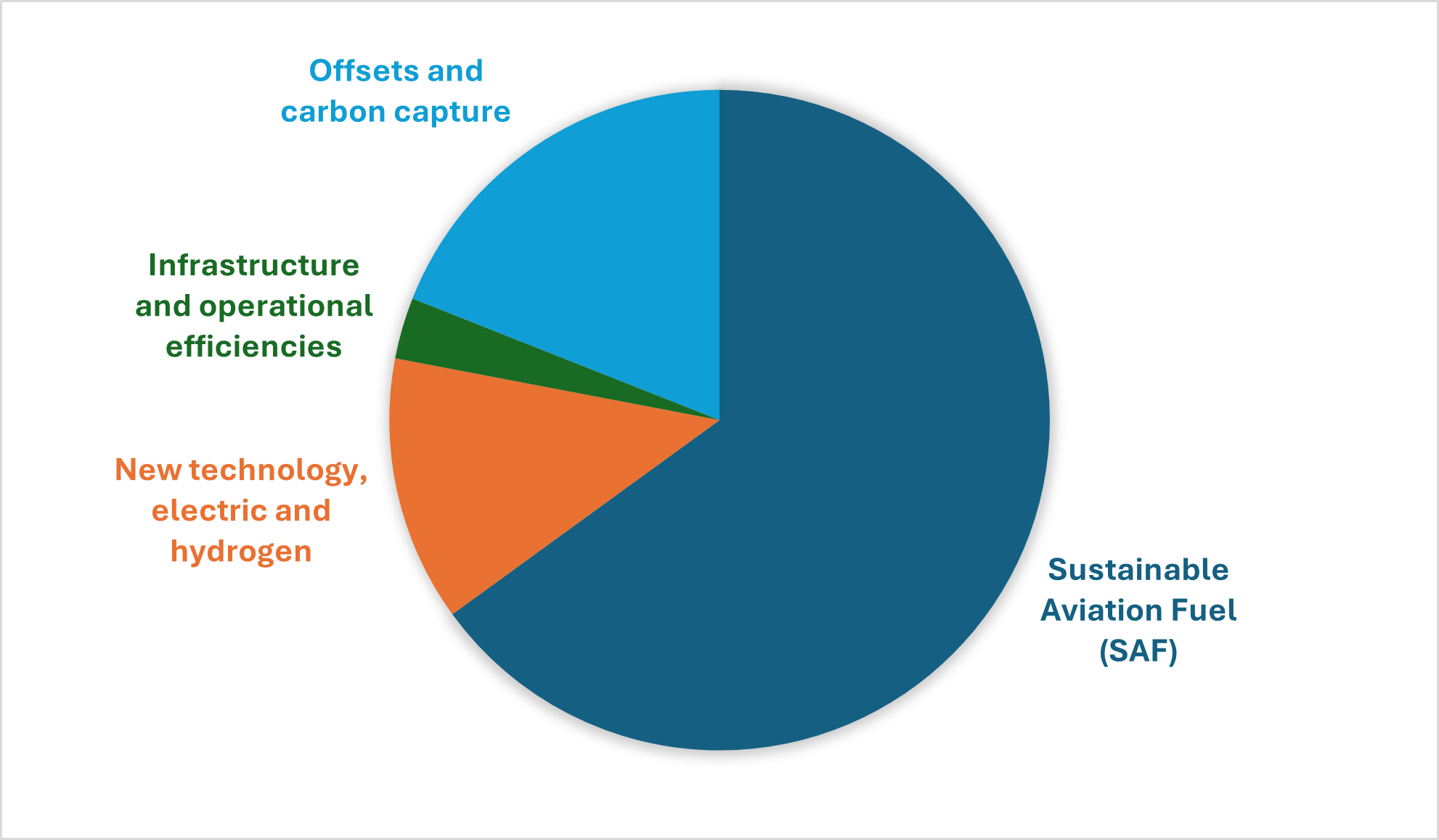

To reach net zero, SAF must deliver 65% of the sector’s emissions reductions. This means producing around 450 billion litres of SAF every year by mid-century. That’s a colossal scaling challenge.

In 2022, only 400 million litres were produced—just 0.09% of the volume needed by 2050. The urgency is clear. SAF is not just a solution; it’s a critical lift-off point for cleaner skies.

IATA (2025). Our strategy towards net zero CO2 emissions. IATA – Sustainable Aviation Fuel (SAF)

So, what is SAF?

Sustainable Aviation Fuel (SAF) is a blended or drop-in replacement for conventional jet fuel (usually kerosene). This means it can be used in today’s aircraft and fuelling infrastructure without modification, making SAF a practical and immediate option for emissions reduction for an industry that is usually considered ‘hard-to-abate’.

“SAF is a lifeline that allows aviation to operate in a way that does not worsen the climate emergency.”

What makes SAF ‘Sustainable’?

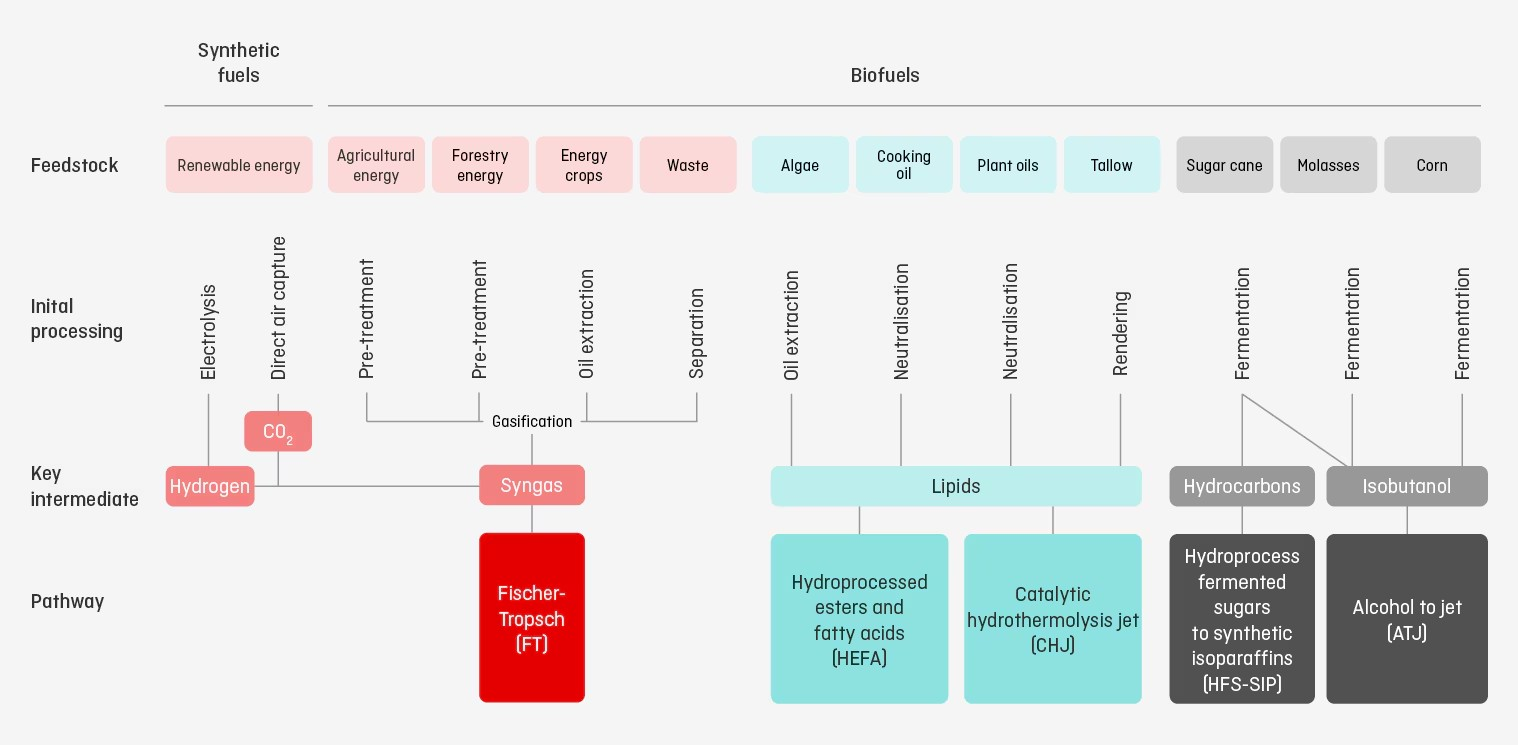

The “sustainable” in Sustainable Aviation Fuel comes from its feedstock and the energy used in its production. Unlike conventional jet fuel, which is refined from crude oil, SAF is made using renewable energy and hydrogen, combined with carbon sourced from more sustainable origins, such as used cooking oil, municipal waste, or even CO₂ captured directly from the air.

Each of these carbon sources has its own benefits and trade-offs, including concerns around food competition, land use change, and carbon intensity (CI). The method of production significantly affects the CI of the fuel, which in turn determines how much it reduces emissions compared to fossil-based jet fuel.

Most SAF on the market today achieves a 65–85% reduction, depending on the feedstocks and processes used. Top-tier SAF, sometimes called ‘premium’, can cut emissions by up to 95%.

To be viable for aviation, SAF must meet strict ASTM standards. These ensure it performs safely in existing aircraft and infrastructure without modifications. The standards also recognise multiple production ‘pathways’, including hydro processed Esters and Fatty Acids (HEFA), Alcohol-to-Jet, and Fischer-Tropsch—all of which produce chemically similar, safe-to-use fuels via different technological routes.

In 2024, CATAGEN became the first SAF producer to submit samples to the EU SAF Clearing House using fuel made from our proprietary E-FUEL GEN technology. This is an important validation step and puts us on our journey towards certification.

Qantas (2025). SAF Production Pathways. IATA – Sustainable Aviation Fuel (SAF)Sustainable aviation fuel | Qantas Group

CATAGEN’s ClimaHtech Green Flight solution aligns with one of these recognised pathways, producing SAF from biomass and a power-to-liquid (PtL) process using an electrically driven reactor powered by renewable energy. While CATAGEN’s core technology also has potential applications in sectors like heavy-duty transport and cement, the aviation industry’s urgency and scale made it our first target.

Why Focus on Aviation?

As discussed, the aviation sector is both a significant emitter and one of the hardest to decarbonise. Due to energy density requirements and strict safety constraints, alternatives like batteries or hydrogen remain unviable for most commercial aircraft. As a result, SAF is currently the only scalable option for decarbonising both existing fleets and those being built today.

CATAGEN is targeting the aviation industry because it presents a practical, near-term opportunity for impactful decarbonisation that has little alternative available. With mandates and incentives accelerating demand, and a strong product-market fit, our technology is built to meet the sector’s most urgent needs.

Immediate Solutions for Net Zero

Modern aircraft are highly optimised and certified for specific fuel types. Redesigning airframes and engines around new fuels would take decades. SAF, by contrast, works within today’s systems and infrastructure, making it the most practical near-term solution to reduce emissions—right now, not starting in 2050. This is crucial if we are to counter the worst impacts of the climate emergency.

Regulatory and Financial Tailwinds

Governments are accelerating SAF deployment through mandates and financial mechanisms which drives demand:

UK: The SAF Mandate, effective from 2025, targets 10% SAF by 2030. It is supported by the £165M Advanced Fuels Fund and an upcoming Revenue Certainty Mechanism, a contract model that derisks SAF investment by guaranteeing a fixed price for producers. This dual-track approach—mandated demand and price certainty—is designed to stimulate early-stage domestic production.

EU: Under ReFuelEU Aviation and the Renewable Energy Directive (RED), SAF blending mandates begin in 2025, rising to 70% by 2050. The EU distinguishes between Bio-SAF and e-SAF, offering differentiated incentives through the EU Emissions Trading System to promote low-carbon pathways.

USA: The Inflation Reduction Act supports SAF through federal tax credits until 2027. Several states have layered on additional incentives. However, with evolving federal priorities, long-term SAF policy in the US remains fluid. The SAF Grand Challenge aims to produce 3 billion gallons annually by 2030, scaling to 35 billion gallons by 2050.

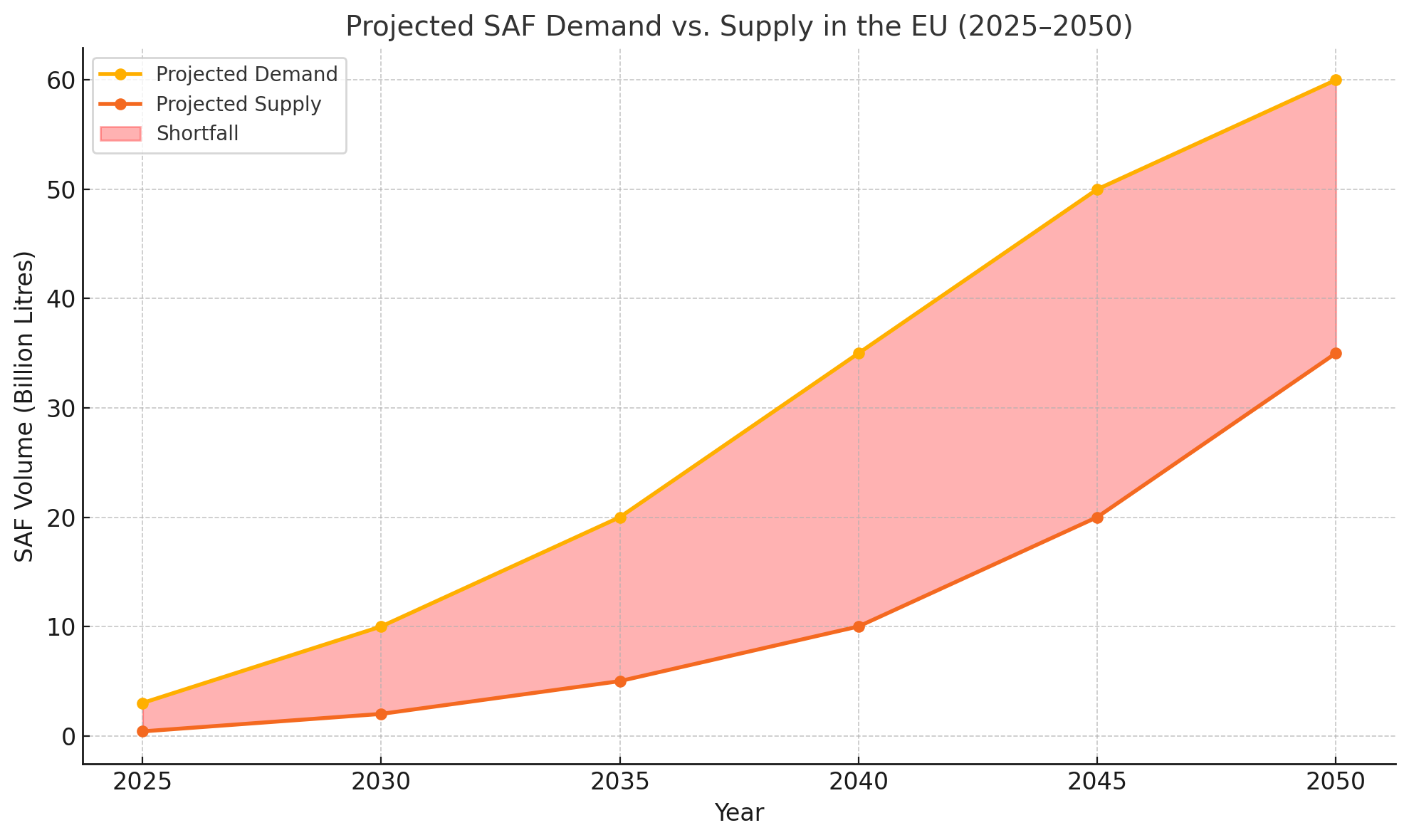

Despite these mandates, current SAF production lags well behind projected demand. Bridging this gap will require coordinated action across policy, investment, and innovation. The graph below shows the estimated demand vs. supply of SAF and the estimated shortfall, using projections and policy targets from the key regulatory frameworks and industry reports above.

CATAGEN’s Strategic Fit

CATAGEN’s Green Flight solution provides a new, scalable pathway for SAF production, delivering lower-carbon fuel that aligns with approved industry standards and supports both compliance and climate targets. With urgency mounting and regulatory pressure increasing, now is the time to deploy technologies that accelerate SAF adoption without compromising operational integrity.

First-of-a-Kind Deployment and Rapid Scalability

CATAGEN is preparing to showcase its ClimaHtech Green Flight solution through a First-of-a-Kind (FOAK) deployment. Set for completion by 2029, this project will showcase decentralised SAF production situated near primary renewable energy sources, enabled by the OMEGA e-reactor. The FOAK will serve as a critical validation of the technology’s readiness, efficiency, and compatibility with real-world energy systems.

Unlike centralised SAF production facilities that require extensive capital investment and lengthy construction timelines, ClimaHtech Green Flight offers a modular and rapidly deployable alternative. This flexibility enables faster rollout and better integration with distributed renewable energy networks, making it ideally suited to meet surging SAF demand in a cost-effective and scalable way.

By combining low carbon intensity, ASTM-aligned processes, innovative e-reactor technology, and decentralised deployment, CATAGEN is not just entering the SAF market—it’s redefining it. ClimaHtech Green Flight represents a leap forward in the quest to decarbonise aviation, offering airlines and governments a viable, impactful path toward net zero.

See what’s next for net zero aviation…

About Ralph:

Ralph Lavery is Head of Technology Applications at ClimaHtech Green Flight and brings substantial expertise in the development and delivery of techno-economic and pre-FEED studies across hydrogen and hydrogen derivative applications.

He is also highly skilled in commercial and business model development for emerging net zero technologies, as well as market segment analysis and assessment. He is currently leading the commercialisation aspects of ClimaHtech Green Flight, bringing disruptive SAF production to the market.

Where Export Durability Risk Actually Starts

by Daniel McAfee, Solutions Engineer, CATAGEN Green Emissions Testing Export emissions issues...

CATAGEN Marks Four Years as Official Ducati Supplier in 2026, Strengthening Technical Partnership

Belfast, (Feb 26) CATAGEN marks its fourth consecutive year as Official Supplier to Ducati in...

Developing Fast Light-Off Tests for Cold Start Emissions

by Daniel McAfee, Solutions Engineer, CATAGEN Green Emissions Testing Cold start emissions...

What is Decentralised SAF?

The SAF bottleneck that no one is talking about: why untapped renewable power could decide the...

Blog: Alternative Fuels and Their Impact on Automotive Aftertreatment Systems

By Matthew McVitty, Head of Business Performance (CATAGEN Green Emissions Testing) The automotive...

CATAGEN Launches World First DAAAC Electric Reactor Using OMEGA Technology

Belfast, (Nov 25) – CATAGEN, Green Emissions Testing proudly announces the extension of its...