Heavy-Duty

Contact an ExpertIndustry Challenges

Emissions legislation

- Uncertainty on the emissions legislation is making it difficult for HD OEMs to understand what will be required for emissions compliance. Durability limits will almost certainly be increased which will add its own set of challenges.

Representative Accelerated Ageing

- A major challenge in our industry is representative accelerating the ageing of what happens in-field. Not uncommon is a mismatch of what in-field vehicles performance and equivalent test bench ageing.

- Uncertainty on quantifying the chemical degradation impacting the ageing strategy.

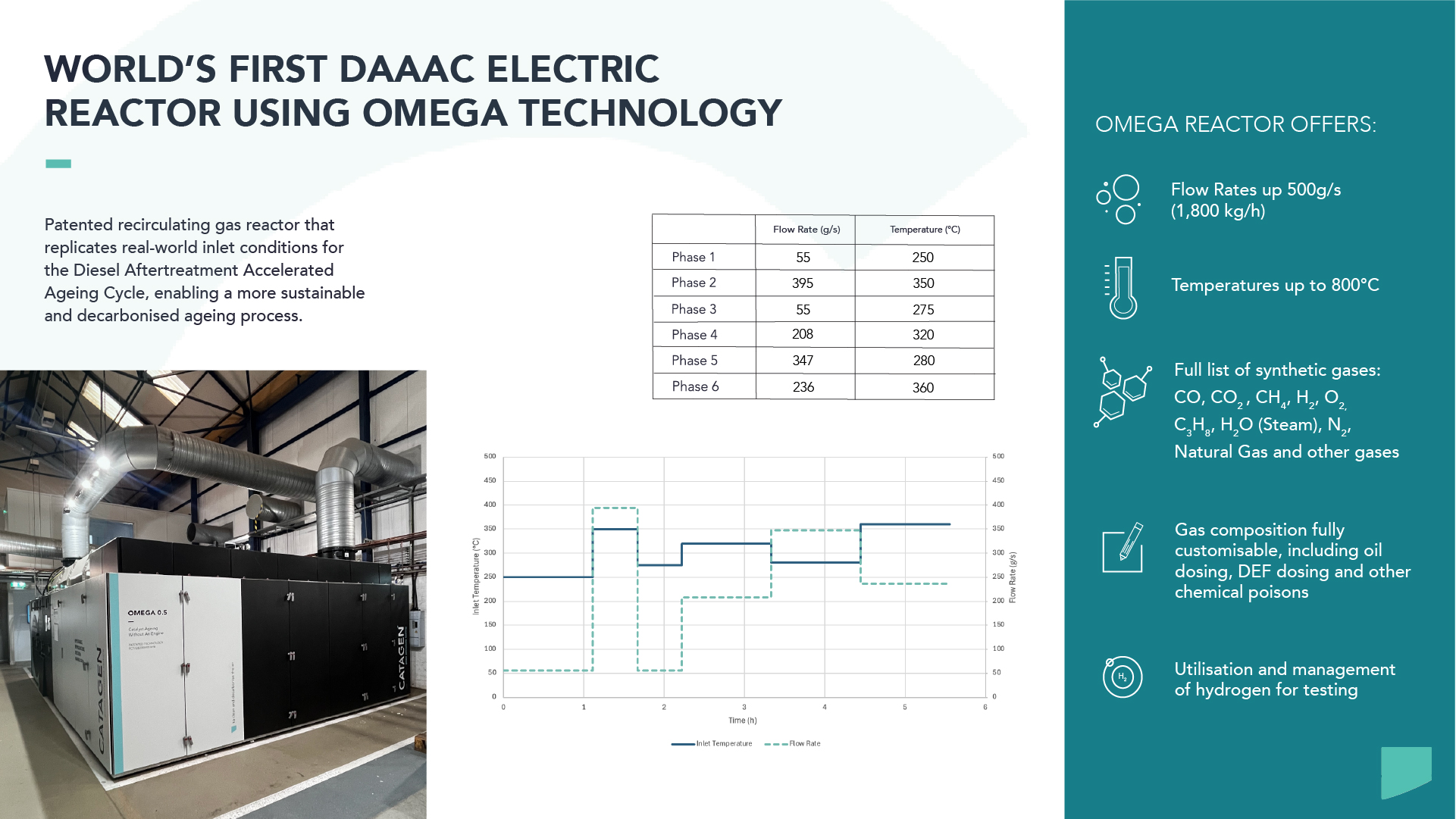

Advanced Aftertreatment Testing with CATAGEN’s Patented OMEGA Technology

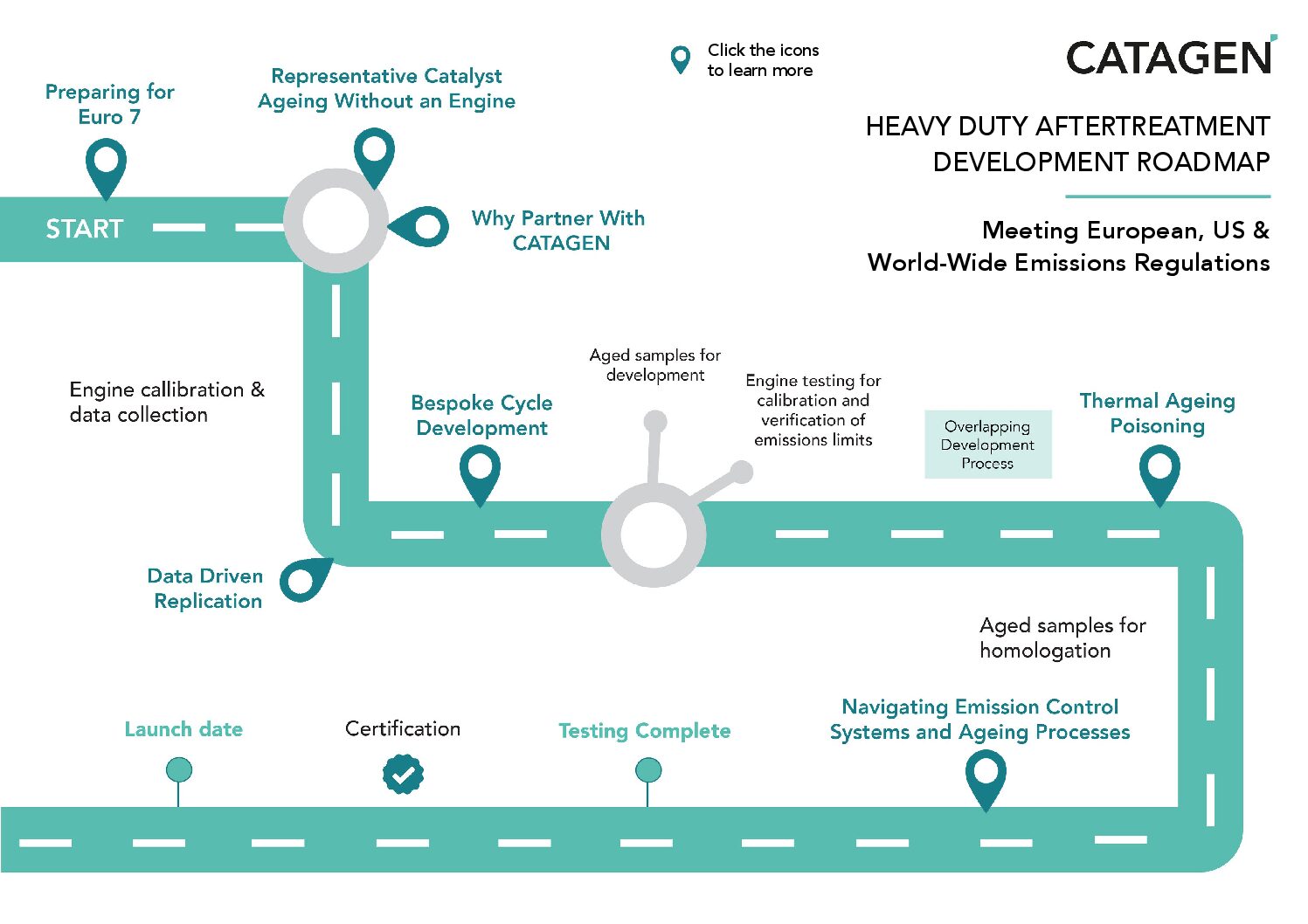

CATAGEN delivers full-scale aftertreatment system testing using our internationally patented OMEGA synthetic gas recirculating reactor. This technology provides highly controlled, repeatable conditions for accelerated ageing and emissions characterisation, helping OEMs meet increasing heavy-duty emissions regulations with confidence.

Our OMEGA reactors allow precise control of catalyst temperature, mass flow and synthetic gas composition. We can introduce key ageing compounds such as ammonia, sulphur and phosphorus to accurately replicate real on-road chemical and thermal degradation. This provides a more representative testing environment than conventional engine-based or steady-state ageing methods.

Using our advanced test capability, we perform a wide range of aftertreatment characterisation tests for heavy-duty applications. These include Ammonia Storage Tests, NOx and NH3 Ratio Tests, NO and NH3 Light-Off Tests and other performance assessments that help determine long-term system durability.

CATAGEN also applies its proprietary Ageing Metric to track ageing experience in real time. This unique metric quantifies thermal and chemical ageing throughout the test programme and enables the development of accurate and representative ageing cycles. It supports OEMs in designing reliable, compliant aftertreatment systems that correlate strongly with real-world operation.

CATAGEN provides industry-leading emissions testing, accelerated ageing and catalyst performance analysis to help manufacturers reduce risk, speed up development and achieve compliance with upcoming regulations such as EPA Phase 3 and Euro 7.

CATAGEN Green Emissions Testing have launched the World's First DAAAC Electric Reactor

What is the Diesel Aftertreatment Accelerated Ageing Cycle (DAAAC)?

The Diesel Aftertreatment Accelerated Ageing Cycle (DAAAC) is a new, more representative method for accelerating the ageing of heavy-duty aftertreatment systems. It has been developed to provide a closer match to real on-road ageing compared to traditional steady-state or engine-based ageing approaches.

The DAAAC is tailored for each customer to ensure the ageing cycle accurately reflects the thermal and chemical conditions that the system experiences in real service. By matching the target engine loads, speeds, temperatures and mass flows, the cycle delivers a more realistic durability assessment.

This method introduces both thermal and chemical ageing mechanisms, including controlled exposure to oil-derived contaminants and sulphur. By integrating these factors with flow-matched engine ageing modes, the DAAAC has shown significantly improved correlation to field-aged hardware.

The DAAAC achieves an accelerated ageing rate of approximately ten times a dynamometer or field test. In practice, this means that 1,000 hours of DAAAC ageing is equivalent to around 10,000 hours of standard ageing. This reduction in testing time allows heavy-duty OEMs to validate long-term performance faster while maintaining high accuracy and regulatory relevance.

INDUSTRY EMISSIONS LEGISLATION

The Euro VI-D legislation for heavy-duty engines approvals entered into force on 1 September 2018 for new types and has applied to all new engines from 1 September 2019. The Euro VI-E entered into force on 1 September 2020 for new types and will apply to all new engines from 1 September 2021. This stage includes consideration of cold-start emissions in data evaluation of the PEMS testing, as well as the measurement and evaluation of PN during the on-road test.

Particle Number (PN) measurement will be included in Euro VI Step E from the beginning for compression ignition engines. For positive ignition engines (natural gas mainly in heavy duty) the PN will need to be declared for monitoring purposes for new type approved vehicles from 01/01/2021 and will need to be complied with from 01/01/2023.

OUR LATEST WEBINARS

Supporting our partners obtain certification with

CATAGEN powered by 100% renewable energy