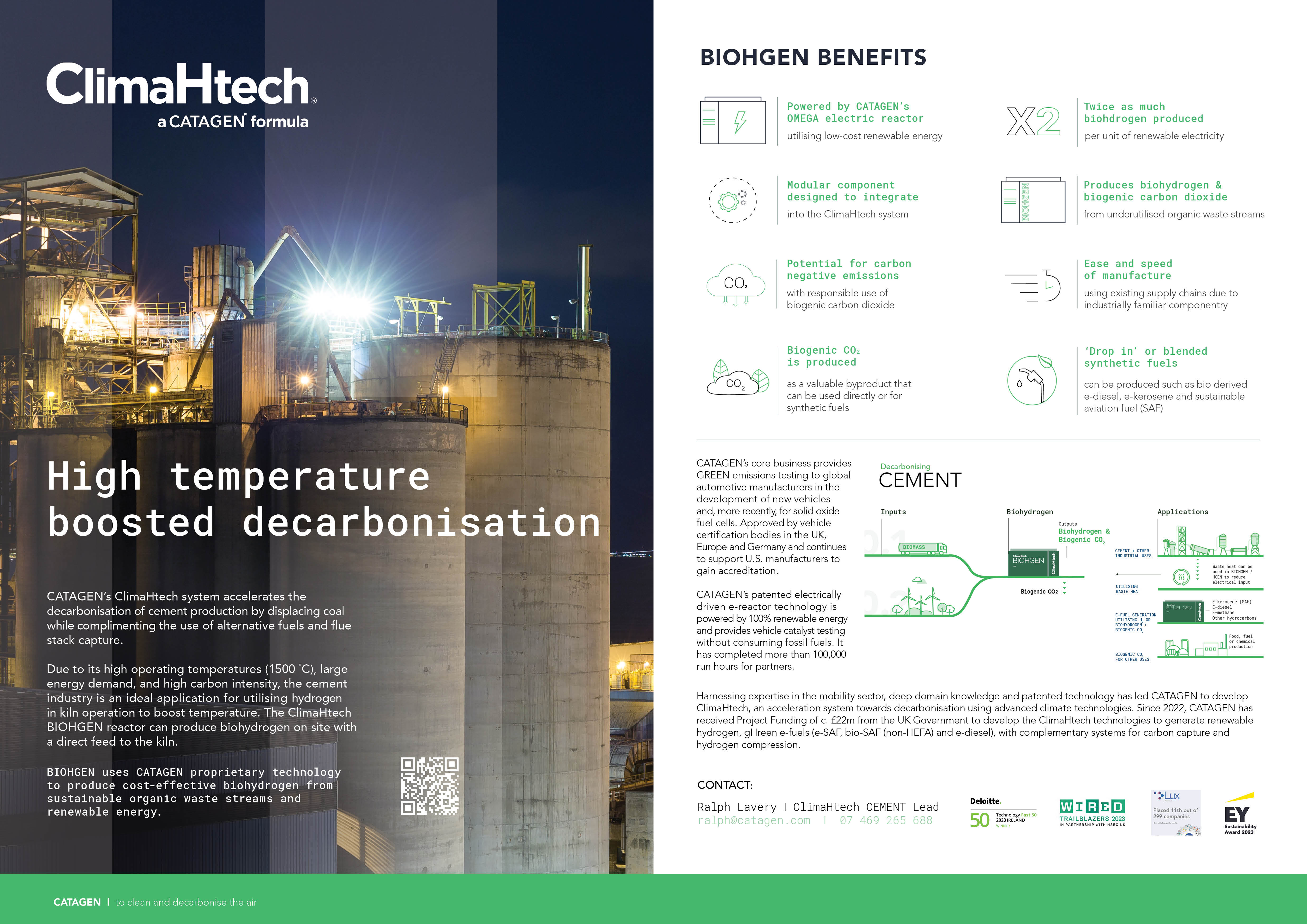

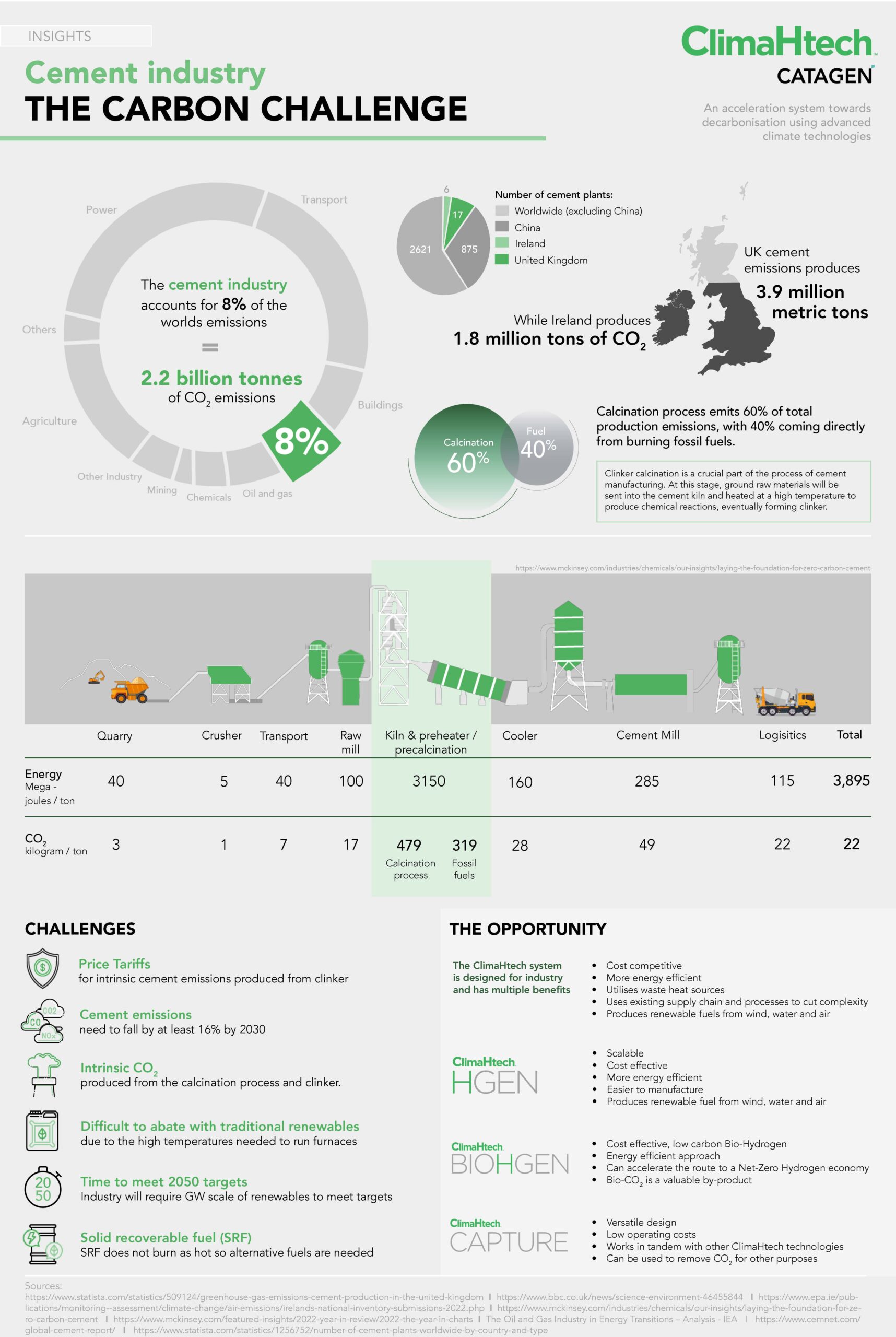

CATAGEN’s ClimaHtech system accelerates the decarbonisation of cement production by displacing coal while complimenting the use of alternative fuels and flue stack capture.

Due to its high operating temperatures (1500 ˚C), large energy demand, and high carbon intensity, the cement industry is an ideal application for utilising hydrogen in kiln operation to boost temperature. The ClimaHtech BIOHGEN reactor can produce biohydrogen on site with a direct feed to the kiln.

BIOHGEN uses CATAGEN proprietary technology to produce cost-effective biohydrogen from sustainable organic waste streams and renewable energy.

View the document below or learn more at ClimaHtech CEMENT – Catagen

CATAGEN Expands Green Emissions Testing Services into North America Following Breakthrough Year and Success at Automotive Testing Expo

announcing plans to expand into North America following a year of record global growth and a highly successful presence at the Automotive Testing Expo in Novi, Michigan.

CATAGEN ranked Fifth Fastest Growing Tech Company and Awarded Impact Prize at Deloitte 2024 Technology Fast 50 Awards

CATAGEN, a leader in green emissions testing and net zero technologies, is delighted to announce its recognition as one of Ireland’s fastest-growing technology companies at the Deloitte Technology Fast 50 Awards 2024. Ranking fifth overall, CATAGEN also received the prestigious Impact Award, presented in association with Meta.

Insight: The opportunity for SAF

Introduction: Aviation’s Growing Carbon Footprint and Sustainable Aviation Fuel In 2022, aviation...

CATAGEN welcomes US Net Zero Advisory Board to it’s headquarters in Belfast

CATAGEN welcomed Andy Marsh CEO Plug Power, Kevin Devlin CEO Renewable Power...

Decarbonising Aviation: CATAGEN at the Farnborough International Airshow 2024

The CATAGEN team visited Farnborough International Airshow this year, which took place on the...

CATAGEN’s ClimaHtech System Decarbonising Cement and Quarrying

CATAGEN’s mission is to clean and decarbonise the air and that is why we are focused...