10 questions with world-leading expert on motorcycle emissions – Dr Kurtis Irwin, Principal Engineer at CATAGEN and recipient of the prestigious Innovate UK Future Leader Fellowship Award. He has been awarded a £1.25m grant to develop global leadership and further expertise in the area of motorcycle emissions control.

In this discussion, Dr Irwin shares his insights working with a world leading toolset and top motorcycle developers with the objective of meeting emissions targets. Reducing tailpipe emissions is one of the biggest challenges in the race to improve air quality. Catalytic convertors need to be perfectly tuned to get the balance right between reducing emissions while being optimised for use. Kurtis spends his time testing, analysing and advising motorcycle OEMs about how to get this balance right.

Q1: Can you describe the current emissions regulations that motorcycles must meet?

A: One of the toughest is called Euro 5 and it has represented a step change in emissions targets. Each new regulation gets more stringent than the last.

Q2: What is the big step change with Euro 5?

A: On Board Diagnostic (OBD II) is being introduced to additionally monitor the catalyst performance, through the installation of a downstream lambda sensor. The up and downstream lambda sensors then communicate with the Engine Management System (EMS) to check an Oxygen Storage Capacity (OSC) and hence, the activity status of the catalyst.

One of the key concerns for our partners, the motorcycle developers, is the measurement of non-methane hydrocarbons. Every new motorcycle sold after 2024 must meet the Euro 5 targets.

Q4: With each new regulation, are the manufacturers having to spend more money?

A: In order to continue to meet the ever more stringent legislations, OEMs are forced to spend more on development, and there’s a knock-on effect, when the suppliers increase their precious metal requirements. Overloading on precious metals can dramatically increase the price point of the component and affect the business case across the production fleet. There is a big economic incentive for OEMs to use the right amount of precious metals and this is where the challenge lies.

Q5: How does testing typically work in the industry?

A: Traditionally, OEMs would run a motorcycle on roads or tracks to test if the catalytic convertor is reducing emissions to the right standard.

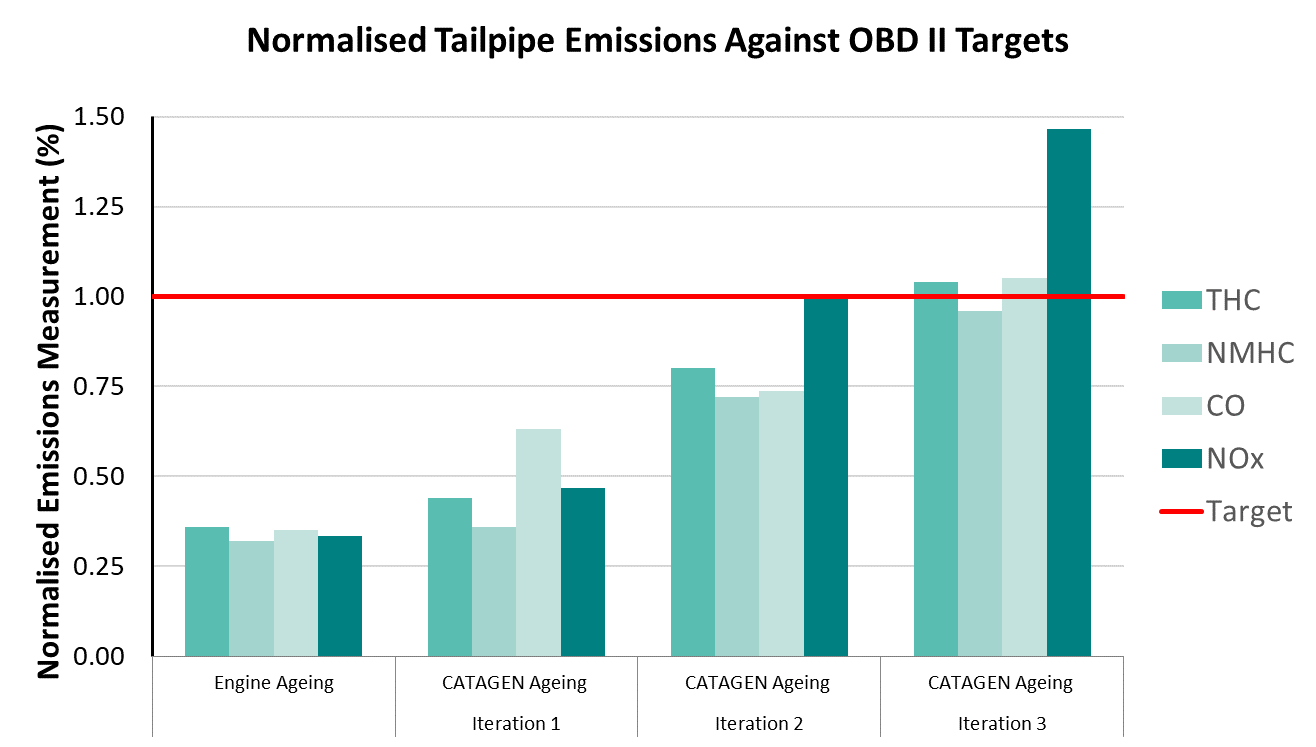

New legislation requires that the test must show that the ‘engine light’ comes on at the right time, i.e. if it’s not reducing emissions to the Euro 5 standard. Experience shows achieving the OBD II target, to trigger the engine light and still meet emissions, has been extremely difficult, as illustrated by the engine data in the graph below.

Q6: How long are you meant to drive a motorcycle?

A: The industry standard is Full Useful Life (FUL). For the Euro 5 standard, this is equivalent to 35,000 kilometres. This is the expected lifespan of a motorcycle, and you still have to pass emissions standards the whole life of the motorcycle.

Q7: This is a European standard only?

A: Yes, but for practical purposes the EU standards are accepted globally, so manufacturers in other areas like Asia or North America are meeting these same standards. (Download CATAGEN’s Ultimate Guide to Motorcycle Emissions)

Q8: What does it mean if the OEM over specifies the catalyst?

A: If the catalyst is overspecified, the amount of precious metals is more than required to pass emissions levels. In other words, it isn’t environmentally or economically optimised.

For example, the cost of rhodium alone has increased by 270% over the past numbers of years due to demand of this natural resource and there are similar trends for platinum and palladium.

Q9: What recommendations would you give to OEMs to optimise the precious metals in their catalysts?

A: We work closely with our customers in a partnership on all of their ageing requirements. Recently there has been more focus on meeting OBD II standards whilst optimising precious metal loadings. This at a high level involves:

-

OEM sends design and specification of catalyst

-

Variation of catalysts with different loadings of precious metals

-

Precious metal loading optimisation is achieved through detailed modelling and ageing, to both FUL and OBD II emissions targets. The predicted loadings are data driven from the modelling of characterisation results.

Q10: Why do this?

A: This analysis on the correct amount of precious metals can significantly reduce the cost of the catalyst before the bike hits production.

At the worldwide scale, this makes a huge difference. There are 200 million motorcycles in the world, and they emit 50 times more hydrocarbons than SUVs.

More about Dr Kurtis Irwin

Kurtis earned a PhD in 2019 in Automotive Catalysis from Queen’s University Belfast. He focused on understanding the degradation rate in automotive catalytic convertors. Prior to his PhD he earned a five-year Masters Degree in Mechanical Engineering.

Download our Motorcycle Guide to Thrifting

More Motorcycle Content: