By Dr Kurtis Irwin, VP Global Catalysis, CATAGEN

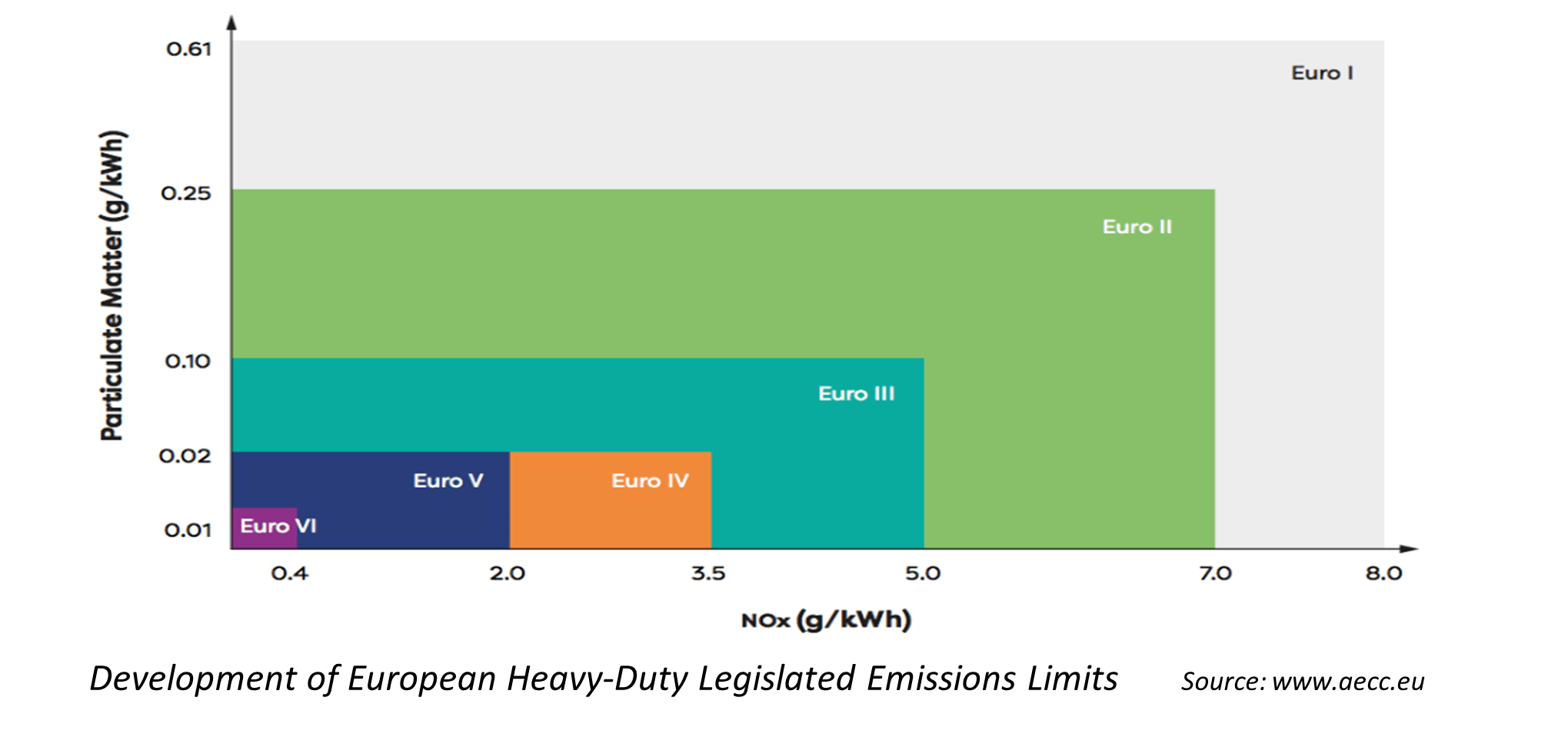

Heavy duty diesel engines are a major source of air pollution, emitting harmful pollutants such as nitrogen oxides (NOx) and particulate matter (PM). To address this issue, governments around the world have implemented strict emissions regulations for heavy duty vehicles. However, these regulations are often complex and subject to change, leading to uncertainties for heavy duty companies and other stakeholders.

What are some of the major uncertainties?

One source of uncertainty is the variation in emissions regulations across different jurisdictions. For example, the European Union and the United States have different standards for NOx emissions, and different countries within the EU have their own unique regulations. This can make it more challenging for heavy duty OEMs to comply with multiple sets of rules, especially if they operate in multiple countries.

Another source of uncertainty is the constant evolution of emissions regulations. As new technologies and scientific research emerge, governments may revise their emissions standards to reflect the latest findings. This can be challenging for OEMs, as they may need to retrofit or replace their existing vehicles to meet the updated standards.

New heavy duty diesel legislation and emissions limits can have a significant impact on the performance and ageing of catalysts. As emissions standards become more stringent, the catalysts used in heavy duty vehicles must be able to reduce emissions to increasingly lower levels. This may require the use of more advanced catalysts or the development of new catalytic technologies.

The implementation of new emissions limits can also impact the ageing of catalysts. As catalysts degrade over time, their effectiveness at reducing emissions may decrease. This can make it more challenging for heavy duty vehicles to meet the new emissions limits, particularly if the catalyst is already significantly degraded.

Furthermore, the FUL distance considered within the regulations require significant investment in both time and costing of fuel and test cell maintenance. The average lifetime of a HDV is approximately 1.2 million kilometres, and with Euro-7 proposing to increase the lifetime distance from the current distance, there are uncertainties over the lifetime performance of aftertreatment systems.

What impact will this have on OEMs?

- Development of new technologies: OEMs may need to invest in research and development to design and produce catalysts that can meet the new emissions limits. This can involve significant upfront costs and may require the development of new technologies or the modification of existing ones.

- Changes to production processes: OEMs may need to make changes to their production processes to incorporate the new catalysts or other emissions control technologies. This can be a time-consuming and costly process, especially if it requires significant changes to the production line.

- Increased costs: The development and implementation of new emissions control technologies can increase the cost of producing heavy duty vehicles. This may impact the profitability of OEMs and could potentially lead to increased prices for consumers.

- Competition: The implementation of new emissions limits may create opportunities for some OEMs, while posing challenges for others. OEMs that are able to effectively design and produce vehicles that meet the new standards may have a competitive advantage, while those that struggle to do so may face challenges in the market.

Overall, the impact of new heavy duty diesel legislation and emissions limits on OEMs will depend on their ability to adapt to the new requirements and effectively incorporate new technologies and processes into their vehicle development plans.

Reliably and repeatably aged catalysts can help OEMs overcome the challenges posed by new heavy duty diesel legislation and emissions limits in several ways:

- Compliance testing: OEMs can use reliably and repeatably aged catalysts in compliance testing to ensure that their heavy duty vehicles meet the new emissions limits. By using catalysts that have been aged to a specific level of degradation, OEMs can accurately assess the performance of their emissions control systems over time.

- Research and development: Reliably and repeatably aged catalysts can be used in research and development efforts to improve the performance and durability of catalysts used in heavy duty vehicles. This can help OEMs to design catalysts that are more effective at reducing emissions and can withstand the rigors of real-world operation.

- Benchmarking: Aged catalysts can be used to benchmark the performance of new catalysts against existing ones. This can help to identify areas for improvement and ensure that new catalysts are at least as effective as existing ones.

- New Technologies: Repeatable and reliably aged catalysts can reduce the risk and expense of exploring new fuels and technologies. With the added complexities of investigating new fuels or H2 engines, requiring alterations throughout the full powertrain, representatively aged catalysts can reduce testing time required on limited available hardware and test cells.

Overall, the use of reliably and repeatably aged catalysts can help OEMs to overcome the challenges posed by new heavy duty diesel legislation and emissions limits by providing a reliable and repeatable means of testing and improving the performance of catalysts. This can help to ensure compliance with the new standards and improve the efficiency and environmental performance of heavy duty vehicles.

However, as new technologies emerge, and regulatory frameworks evolve the industry must prepare for an even greater challenge—one that could redefine the future of heavy-duty transportation altogether.

Stay tuned for Part 2, where we delve into the regulatory shifts and the innovations set to revolutionise emissions control.

To speak to one of our team about how we could help you with catalyst ageing and aftertreatment testing, follow the link below.

More Content:

CATAGEN Expands Capabilities with World’s First DAAAC (Diesel Aftertreatment Accelerated Ageing Cycle) Electric Reactor Using OMEGA Technology

Bio: Dr Kurtis Irwin

Kurtis is the VP of Global Catalysis. He has over 10 years of experience specialising in after-treatment systems and catalysts. He is a Doctor of Philosophy (Ph.D.) focusing on mechanical engineering and he was recently awarded the UKRI Future Leader Fellowship award.