By Matthew Elliott, AUTO Technical Specialist at CATAGEN

The Challenge

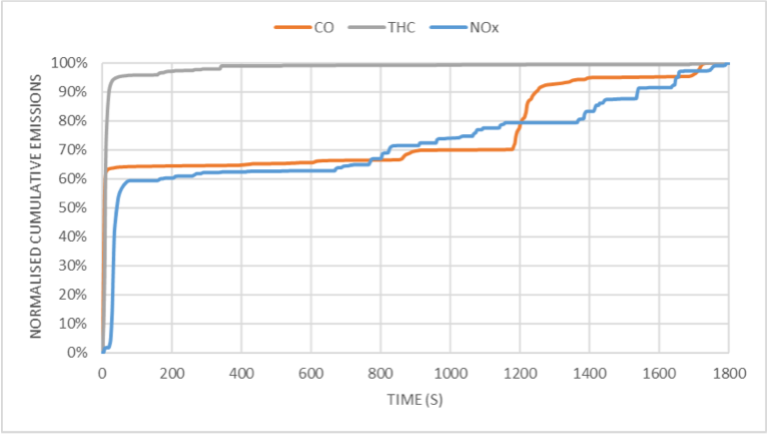

When we look at the modal emissions over a drive cycle, we want to see the same shape replicated as compared with a vehicle aged catalyst. If the shape of the modal trace of NOx, hydrocarbons & CO emissions is very different, then an alternative solution to replicate the cold start emissions is required.

Cold Start Emissions

Cold start emissions occur at the start of engine ignition when the engine is running, therefore polluting, and the catalyst is not hot enough to convert the harmful gases into non-harmful gases efficiently through a three-way catalyst.

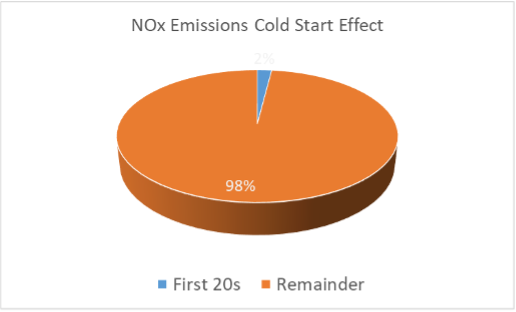

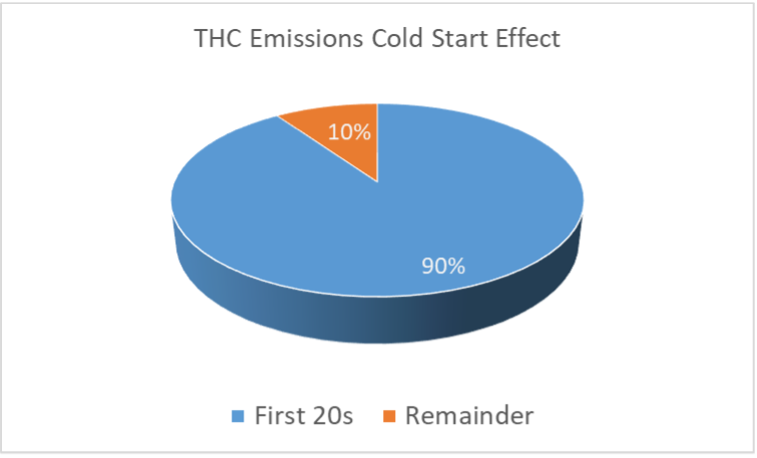

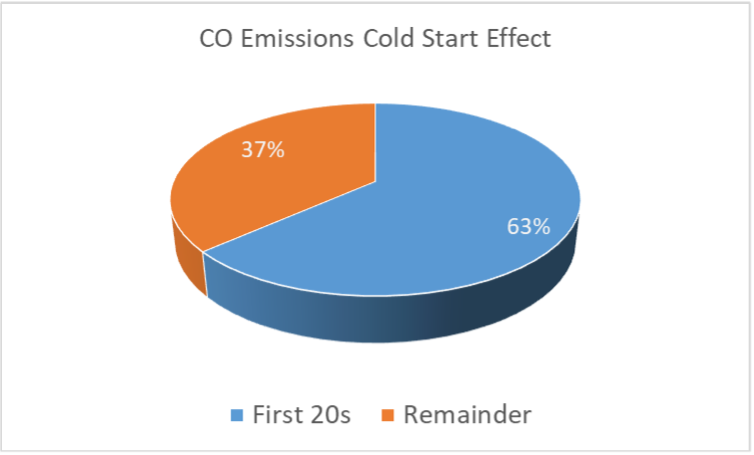

Figures 1, 2 & 3 show the percentage of each pollutant emitted over a real drive cycle for a light duty auto manufacturer of an 1800second drive cycle.

Figures 1, 2 and 3 demonstrate that in order to ensure compliance with the legislation, manufacturers must fully understand the cold start emissions from their aftertreatment system.

Excluding NOx, the majority of CO and THC is emitted during a drive cycle in the first 20 seconds of the cold start. This poses a serious challenge to our industry; how do we reduce the total percentage of pollutants emitted in the cold start phase of driving?

If we can improve the cold start emissions and reduce the time it takes to convert the gases, then the aftertreatment systems become more efficient and compliant.

Hybridisation

This issue is not solely owned by the internal combustion engine (ICE) but also poses a challenge to hybrid engines which are still impacted by the cold start challenge.

Hybrid vehicles do not pollute when running in electric form however when switched to the ICE begin polluting and require aftertreatment systems to convert the gases into non-harmful gases. The challenge is that the three-way catalyst must be heated to ensure conversion, which doesn’t occur when the vehicle is in electrical mode.

Potential Solutions

There are a range of potential solutions under development to reduce cold start emissions but the maturity of these solutions differ depending on the technologies and applications. To name but a few:

· Electrically heated catalysts

· Pre-heating of the emissions control system

· Increased precious metal loadings

· Integration of close-coupled catalysts

Each of these potential solutions in their own right bring their own challenges:

– What is the electrical heating strategy for the catalyst before the engine is ignited?

– What additional battery power is required to heat the emissions control system?

– Will the price of Rhodium, Pallidum & Platinum continue to increase?

– How do we package an additional catalyst/electical heating into the system?

Currently, there isn’t a “one size fits all” solution to this challenge, it may be a combination of solutions or a new alternative solution that will be developed in the race to EV and hybrid. CATAGEN can provide expertise to support the decision making in the development of your hybrid aftertreatment design.

More Auto Content: